Provide One-stop Solutions For Si Materials

Technical Parameters

| Project | Content |

|---|---|

| Diameter | 2"(50.8mm)、3"(76.2mm)、4"(100mm)、5"(125mm)、6"(150mm)、8"(200mm)、12"(300mm) |

| Grade | Prime、Test、Dummy、Reclaimed |

| Growth Method | CZ、FZ |

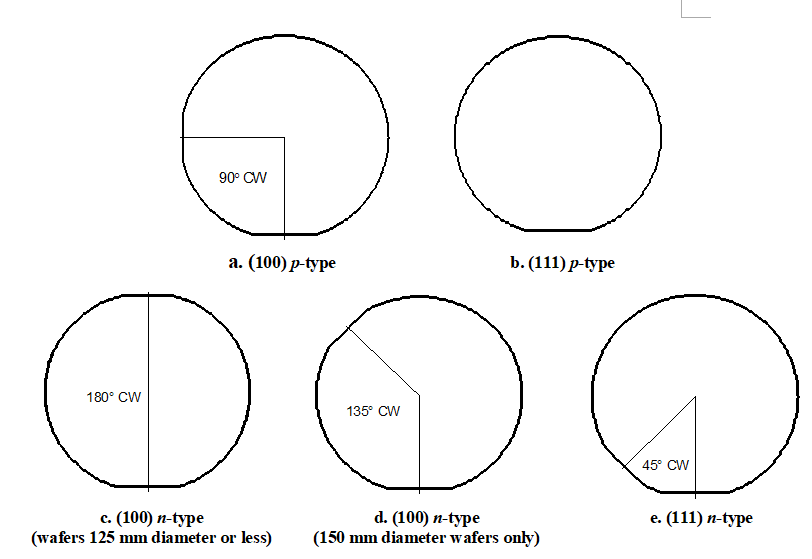

| Orientation | 100 , 111 , 110 |

| Type/Dopant | P Type/Boron、 N Type/Phos、 N Type/As、N Type/Sb |

| Resistivity | From 0.001 to 10000 ohm-cm |

| Thickness (μm) | 50~3000μm |

| Thickness Tolerance | Standard ± 25μm、Maximum Capabilities ± 5μm |

| TTV (μm) | Standard < 10 um、Maximum Capabilities <5 um |

| Bow/Warp (μm) | Standard <40 um、Maximum Capabilities <20 um |

| Finish | As cut、Lapped、 Etched、 SSP、DSP、etc |

| Off cut | up to 7 deg |

| Particle | <10@0.5um、<10@0.3um、 <10@0.2um |

Technical Advantages

Ultra-Precision Surface Control:Atomic-level surface roughness (<0.3nm Ra) with double-side polishing (DSP) technology, enabling defect-sensitive MEMS and nanoscale sensor fabrication.

Flexible Process Adaptability:Compatible with both p-type (Boron-doped) and n-type (Phosphorus/Arsenic-doped) configurations, covering resistivity from 0.001 to 100 Ω·cm for R&D versatility.

Sustainable Cost Efficiency:Reclaimed-grade wafers reduce production costs by 40% while maintaining <15 particles/cm² cleanliness, ideal for non-critical process verification.

Rapid Prototyping Enabler:Thickness tolerance ±10μm and instant-access 100/111 crystal orientations accelerate optoelectronic device development cycles by 30%.

Cross-Industry Compatibility:SEMI-standardized edge profiling ensures seamless integration with 150mm/200mm fab tools for hybrid semiconductor-photovoltaic workflows.

Zero-Contamination Guarantee:Class 10 cleanroom packaging with nitrogen-sealed containers prevents oxidation during storage and shipping.