Provide One-stop Solutions For Si Materials

- High dielectric strength (up to 10 MV/cm) for reliable insulation.

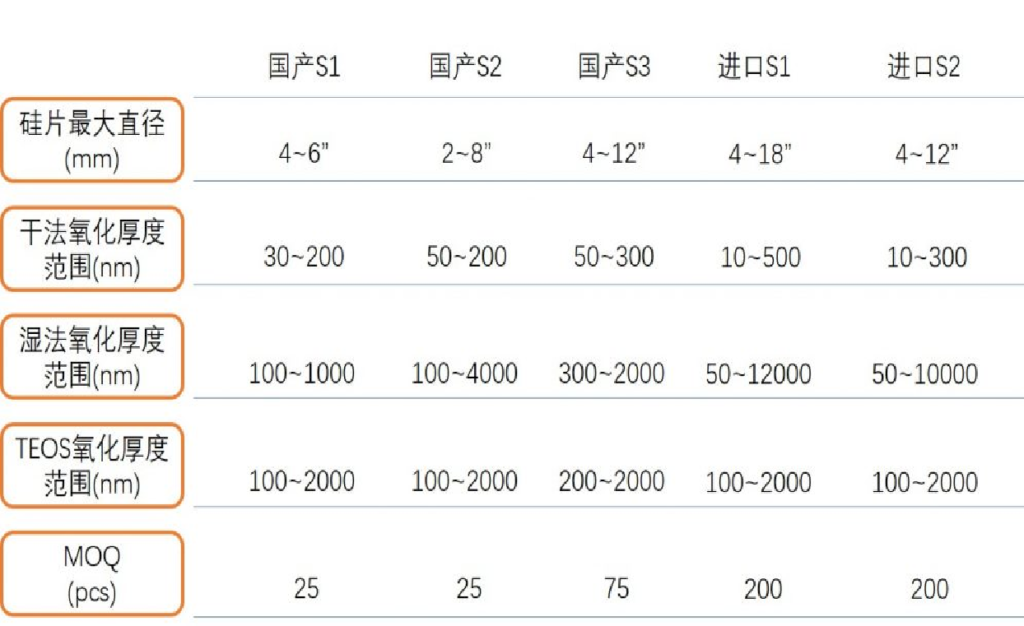

- Uniform thickness control (ranging from nanometers to micrometers) via dry or wet oxidation processes.

- Chemical inertness and resistance to harsh etching environments.

Technical Parameters

| Project | Content |

|---|---|

| Diameter | 2"(50.8mm)、3"(76.2mm)、4"(100mm)、5"(125mm)、6"(150mm)、8"(200mm)、12"(300mm) |

| Grade | Prime、Test、Dummy、Reclaimed |

| Oxidation Technique | Wet oxidation or Dry oxidation |

| Oxide Thickness | 100 Å ~ 15µm |

| Tolerance | +/- 5% |

| Surface | Single Side Oxidation(SSO) / Double Sides Oxidation(DSO) |

| Furnace | Horizontal tube furnace |

| Gas | Hydrogen and Oxygen gas |

| Temperature | 900℃ ~ 1200 ℃ |

| Refractive index | 1.456 |

Technical Advantages

Ultra-High Purity & Uniformity: Our silicon oxide wafers (SiO₂) are engineered with 99.999999% purity, ensuring minimal defects and exceptional uniformity for precise semiconductor fabrication and MEMS applications.

Superior Thermal Stability: Withstanding extreme temperatures up to 1200°C, our SiO₂ wafers maintain structural integrity in high-temperature processes like thermal oxidation and CVD, critical for advanced IC manufacturing.

Optimal Dielectric Performance: Featuring high dielectric strength (>10 MV/cm), our oxide layers enable efficient electrical insulation, reducing leakage currents and enhancing device reliability in microelectronics and power semiconductors.

Chemically Inert Surface: The inert nature of our SiO₂ wafers resists corrosion from acids, bases, and plasma, ideal for harsh etching environments and long-term stability in MEMS and optoelectronic devices.

Nanoscale Precision: Customizable oxide thickness (1nm to 2µm) and ultra-smooth surface roughness (<0.5nm RMS) support cutting-edge nanotechnology, photolithography, and quantum device research.

Versatile Integration: Compatible with silicon substrates and standard CMOS/MEMS processes, our wafers streamline production of sensors, optical coatings, and gate oxides, accelerating time-to-market.

Eco-Friendly Durability: Engineered for high environmental resistance (moisture, UV, oxidation), our SiO₂ wafers extend product lifespans in aerospace, automotive, and renewable energy systems.