Provide One-stop Solutions For Si Materials

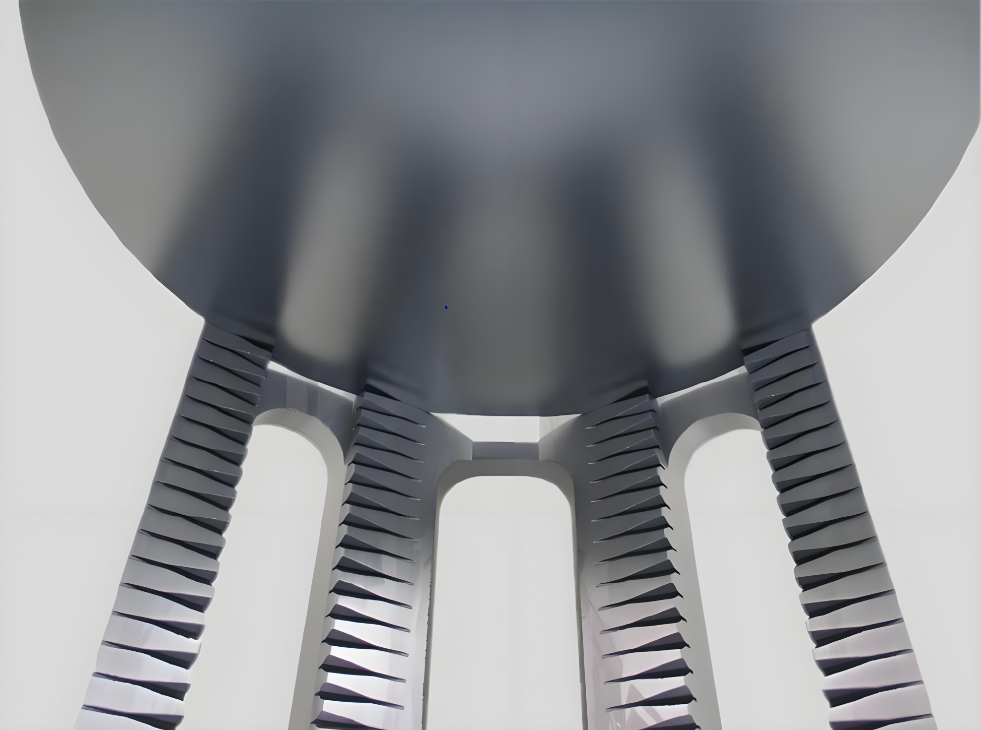

- High-Temperature Stability: Silicon boats withstand extreme temperatures up to 1400°C, making them ideal for applications like annealing and epitaxial growth in horizontal or vertical furnaces.

- Material Compatibility: High-purity silicon ensures thermal expansion coefficients closely matched to silicon wafers, preventing warping or lattice mismatch during thermal cycling.

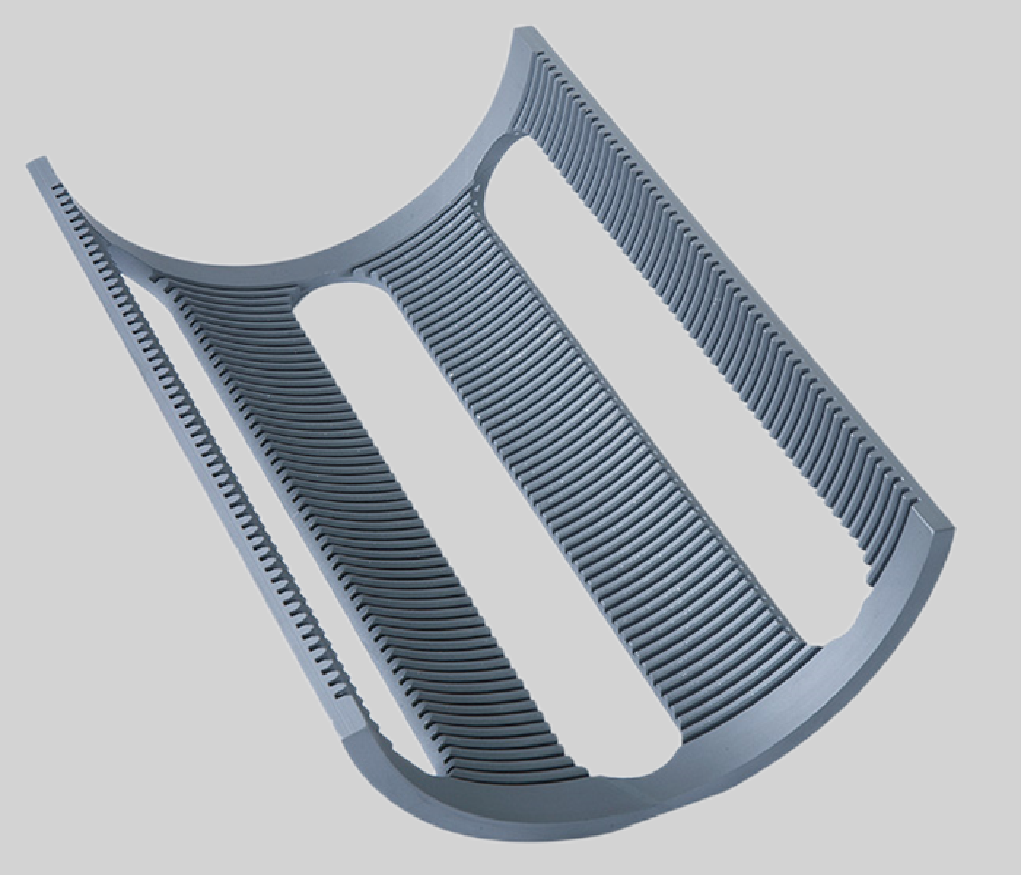

- Customization: Available in sizes from 200mm to 300mm, with options like inclined grooves for increased wafer loading density and anti-slip designs to enhance stability during automation.

- Low Particle Emission: Advanced cleaning processes ensure sub-ppb levels of metallic impurities, critical for maintaining yield in high-precision logic and memory chip fabrication.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >9N |

| 2 | Material | / | Mono / Poly |

| 3 | Diameter scale | mm | 0~1300 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Operating Temperature | ℃ | <1250 ℃ |

| 8 | Surface treatment | / | Polishing |

Technical Advantages

Cost-Effective High-Temperature Solution:Ideal for oxidation/annealing processes below 1000°C, offering 40% cost savings versus monocrystalline alternatives.

Enhanced Thermal Shock Resistance:Grain boundary structure absorbs thermal stress, reducing crack risks in rapid thermal cycling applications.

Compatibility with Legacy Processes:Proven reliability in 150mm/200mm wafer manufacturing for power devices and analog ICs, with minimal process re-qualification.

Batch Process Scalability:Supports large-volume production with cycle lifetimes exceeding 5,000 runs in non-critical contamination environments.

Customizable Surface Texturing:Engineered contact points minimize wafer imprinting while maintaining alignment stability for 8-inch wafer batches.