Provide One-stop Solutions For Si Materials

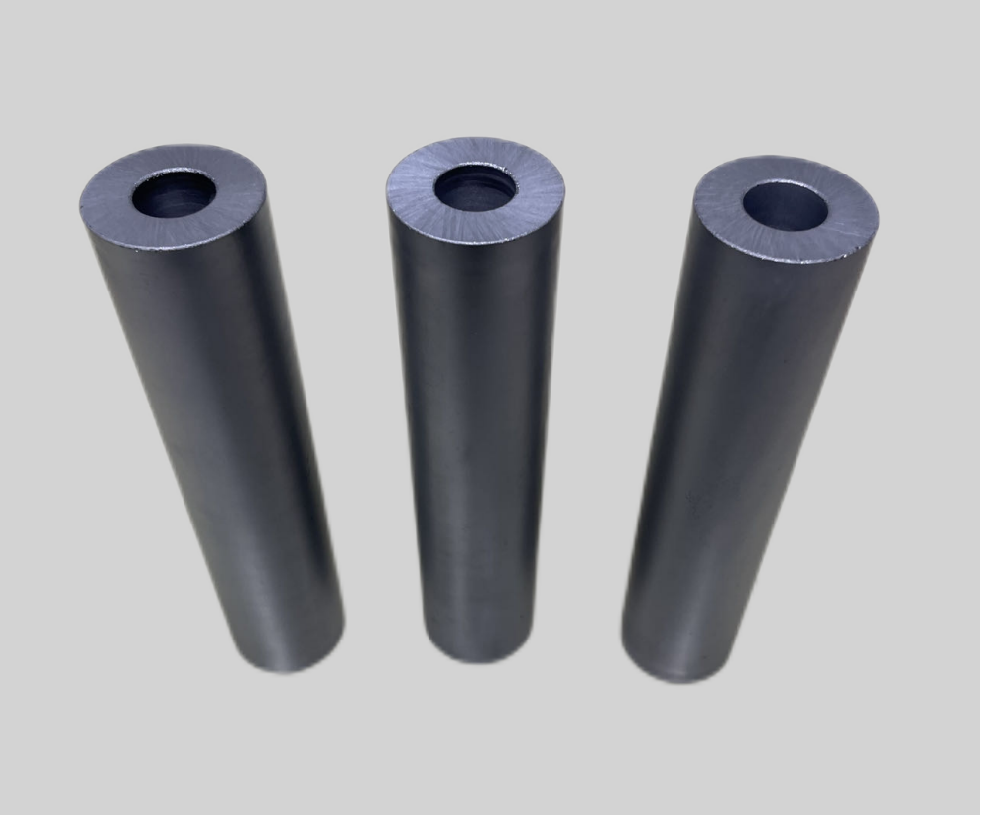

Polycrystalline silicon tubes are high-performance ceramic components widely used in semiconductor manufacturing and vacuum processing industries. These tubes are engineered with high purity (99.9999%) and superior thermal stability (withstanding temperatures up to 1200°C), making them ideal for critical applications such as exhaust ring blank materials and semiconductor etching components.

In the semiconductor industry, polycrystalline silicon tubes are used for wafer processing and thin – film deposition. In the solar energy field, they play a crucial role in the manufacturing of solar cells. With customizable sizes and shapes, polycrystalline silicon tubes can meet different application requirements, providing reliable solutions for modern industrial production.

- Semiconductor Industry: Used in gas delivery systems and etching equipment to prevent wafer contamination.

- Pharmaceuticals: Ensures sterile conditions during drug formulation and bioprocessing.

- Research Labs: Critical for analytical instruments requiring contamination-free sample handling.