Provide One-stop Solutions For Si Materials

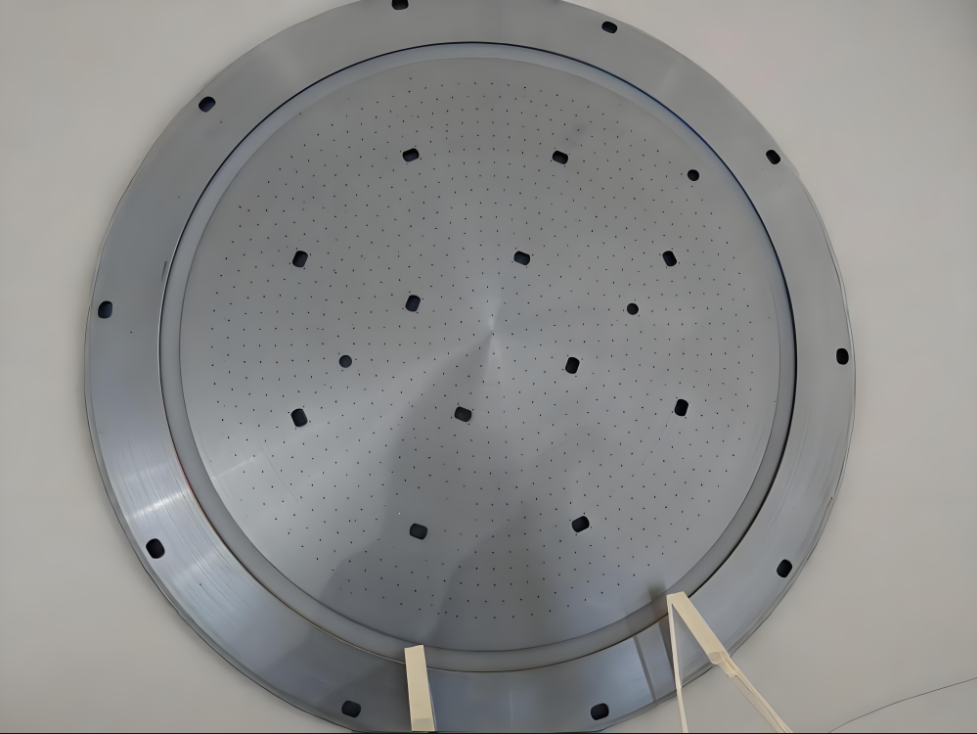

- Dual Functionality: Serve as both electrical conductors to generate plasma and gas distribution plates to deliver etching gases (e.g., SF₆, CF₄) uniformly across the wafer surface.

- Precision Machining: Micro-engineered with thousands of sub-millimeter holes (e.g., 0.45mm diameter) to ensure gas flow uniformity, critical for maintaining etch rate consistency and minimizing defects.

- Material Compatibility: High-purity silicon electrodes resist chemical attack from aggressive etchants, while SiC coatings enhance durability in high-temperature environments (up to 1400°C).

- Customization: Available in sizes ranging from 200mm to 450mm, with design variations including vacuum channels, anti-static surfaces, and alignment features for automated handling systems.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >6N |

| 2 | Material | / | Mono Si |

| 3 | Diameter scale | mm | 0~500 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Dopant | / | B、P、Ga、As、Sb |

| 8 | Surface treatment | / | Polishing |

Technical Advantages

Ultra-High Purity Silicon (99.9999%):Minimizes contamination risks in critical processes like EUV etching, ensuring defect-free wafer surfaces.

Superior Plasma & Chemical Resistance:Withstands aggressive plasmas (CF₄, Cl₂, SF₆) and reactive gases, maintaining performance over 15,000+ process cycles.

Precision Gas Distribution Design:Optimized showerhead hole geometry achieves ±1% gas flow uniformity, enabling sub-3nm etch rate variation across 300mm wafers.

Extreme Thermal Stability (up to 600°C):Monocrystalline silicon structure prevents warping under rapid thermal cycling, critical for high-power RF plasma environments.

Low-Particle Surface Technology:Mirror-polished finish (Ra <0.3nm) reduces micro-arcing and particle generation, improving yield to >99.98%.

Advanced RF Coupling Efficiency:Engineered dielectric properties ensure 95%+ RF energy transfer, enhancing plasma density and process repeatability.