Provide One-stop Solutions For Si Materials

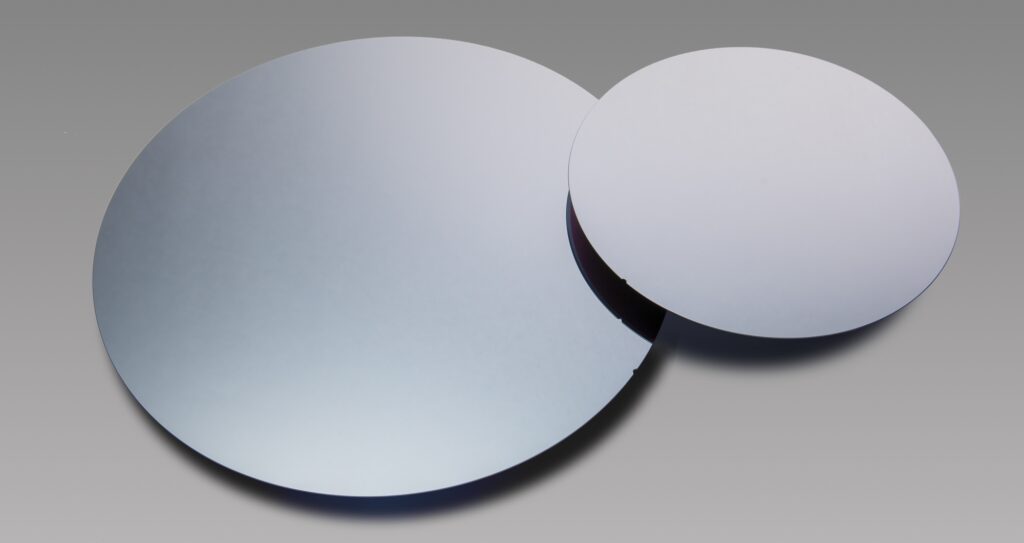

Jingge’s 200mm (8-inch) to 300mm (12-inch) silicon wafers are engineered for high-volume manufacturing of advanced logic ICs, 3D NAND, and CIS image sensors. Available in Prime (sub-0.2nm Ra surface, ≤0.3ppb metal contamination), Test (equipment stress testing), Dummy (thermal budget validation), and Reclaimed (post-process recycling) grades, these substrates support double-side polishing (DSP) for EUV lithography and single-side polishing (SSP) for epitaxial deposition.

Prime-grade 300mm wafers achieve total thickness variation (TTV) <1μm with ultra-low COP defects (<5/cm²), critical for sub-7nm node production. All wafers comply with SEMI M1/M73 standards, offering customizable parameters:

Resistivity: 0.001-10000 Ω·cm (p-type Boron/n-type Phosphorus)

Oxygen content: <12ppma (CZ/FZ crystal growth)

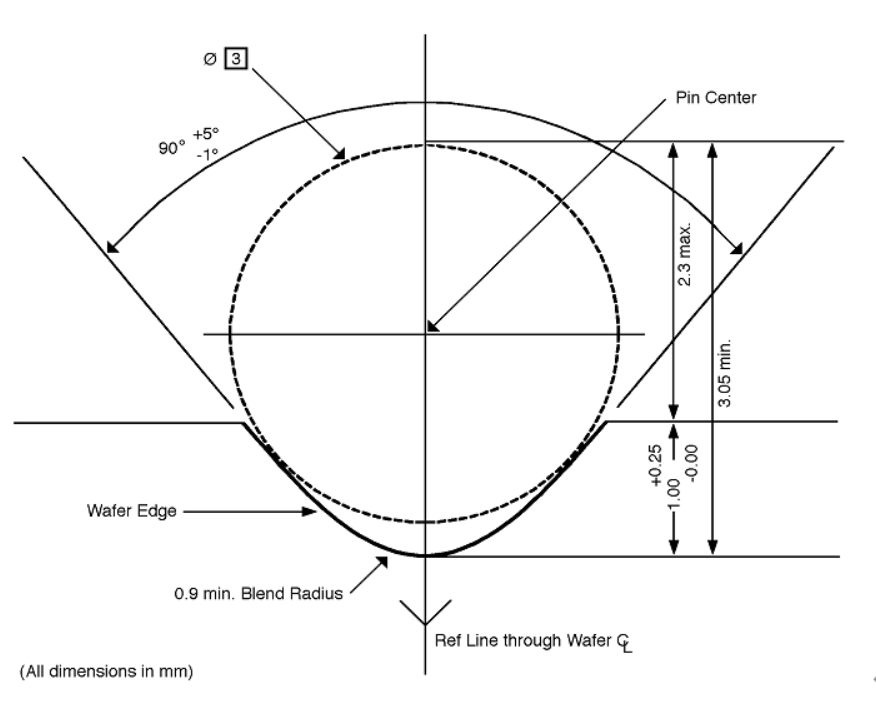

Edge exclusion: ≤2mm (300mm) / ≤1.5mm (200mm)

Reclaimed wafers reduce fab OPEX by 45% while maintaining ≤25 particles/addon (>0.2μm) for non-critical layers. Compatible with 450mm-ready automation systems, our 200-300mm portfolio enables seamless scaling from legacy 90nm to cutting-edge 3nm GAA architectures.

Technical Parameters

| Project | Content |

|---|---|

| Diameter | 2"(50.8mm)、3"(76.2mm)、4"(100mm)、5"(125mm)、6"(150mm)、8"(200mm)、12"(300mm) |

| Grade | Prime、Test、Dummy、Reclaimed |

| Growth Method | CZ、FZ |

| Orientation | 100 , 111 , 110 |

| Type/Dopant | P Type/Boron、 N Type/Phos、 N Type/As、N Type/Sb |

| Resistivity | From 0.001 to 10000 ohm-cm |

| Thickness (μm) | 50~3000μm |

| Thickness Tolerance | Standard ± 25μm、Maximum Capabilities ± 5μm |

| TTV (μm) | Standard < 10 um、Maximum Capabilities <5 um |

| Bow/Warp (μm) | Standard <40 um、Maximum Capabilities <20 um |

| Finish | As cut、Lapped、 Etched、 SSP、DSP、etc |

| Off cut | up to 7 deg |

| Particle | <10@0.5um、<10@0.3um、 <10@0.2um |

Technical Advantages

Sub-nm Surface Precision:Ultra-smooth DSP (Double-Side Polished) surfaces with Ra <0.2nm, certified by AFM metrology, enabling defect-free EUV lithography for 3nm GAA transistor patterning.

Industry-Leading Defect Control:COP (Crystal Originated Pit) density <5/cm² on 300mm Prime wafers, achieving 99.98% yield in 3D NAND vertical stacking processes.

Thermal Stability Mastery:Oxygen content stabilized at 8-12ppma (±0.5ppma) via CZ/FZ crystal growth, minimizing wafer warpage <0.5μm under 1000°C epitaxial deposition.

Future-Ready Compatibility:300mm wafers with ≤2mm edge exclusion zone, fully compatible with 450mm fab automation interfaces for hybrid production lines.

Cost-Smart Sustainability:Reclaimed 200mm wafers reduce COO (Cost of Ownership) by 45% while maintaining ≤25 particles/addon (>0.2μm) for PMIC and analog IC production.

Doping Precision Engineered:Resistivity uniformity ±1% across 300mm wafers, supporting 0.001-10000 Ω·cm ranges for GaN-on-Si and SiC hybrid power devices.

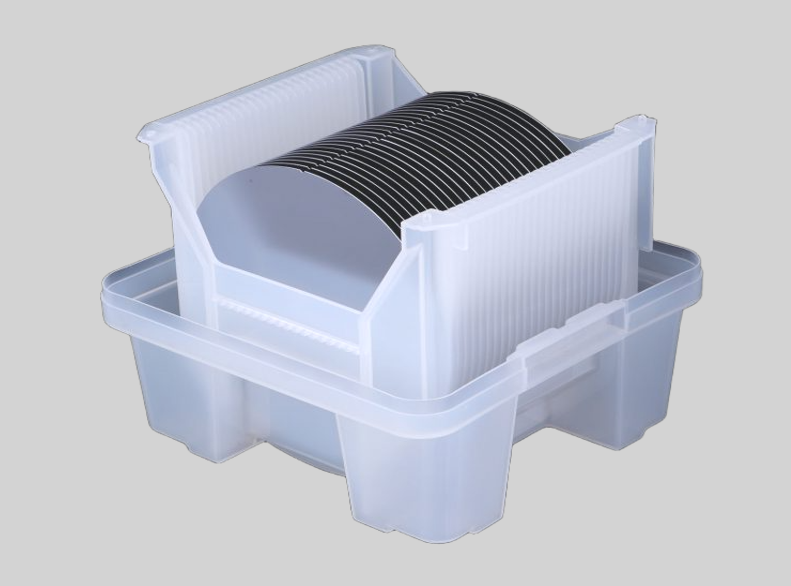

Zero-Contamination Assurance:Class 1 cleanroom packaging with <0.3ppb metal contamination (Cu/Fe/Al), validated by GD-MS and TXRF analysis.