Provide One-stop Solutions For Si Materials

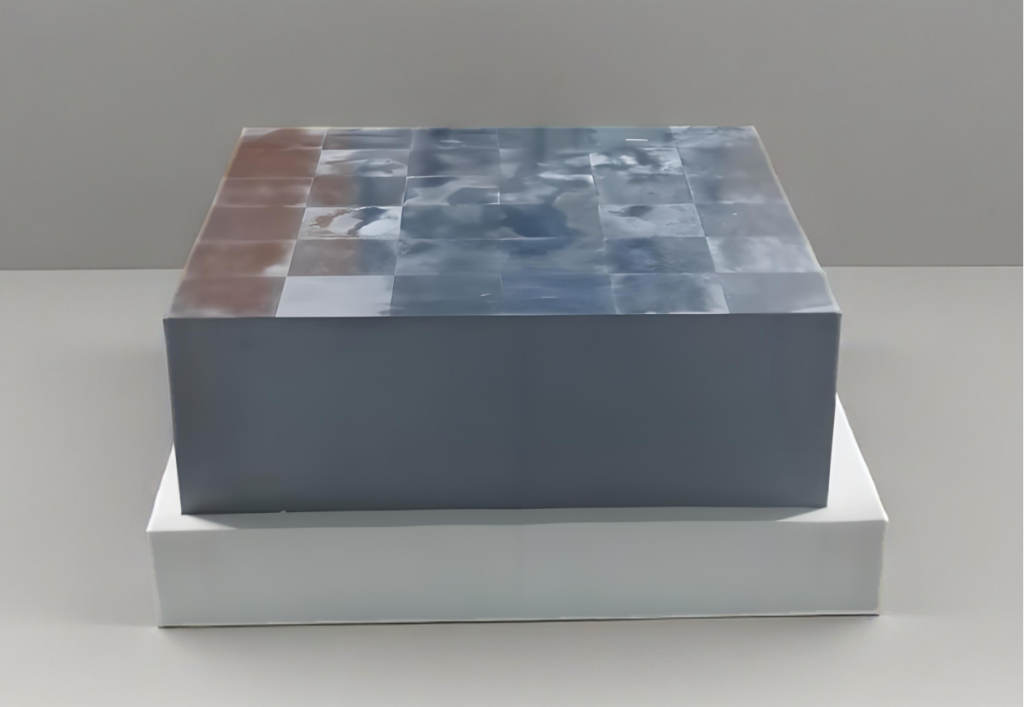

Home / Products / Si Material / Cast Mono Silicon

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >6N |

| 2 | Diameter scale | mm | 0 ~ 800 |

| 3 | Type/Contains | / | P type/ N type |

| 4 | Resistivity | Ω•cm3 | <0.02 / 0.02~1 / 1~5 |

| 5 | Oxygen saturation | ppma | ≤10 |

| 6 | Carbon saturation | ppma | ≤10 |

Technical Advantages

Ultra-Large Monocrystalline Size:Achieve 800mm x 800mm monolithic silicon ingots, enabling seamless processing of large-sized silicon components while minimizing material waste and joint defects.

Low Dislocation Density:Deliver dislocation density <10³ cm⁻², comparable to Czochralski (CZ) monocrystalline silicon, ensuring exceptional structural uniformity for precision semiconductor and industrial applications.

Cost-Effective Production:Leverage cast-grown technology to reduce manufacturing costs by 20%-30% versus traditional CZ methods, while maintaining single-crystal performance.

Superior Machinability:Optimized crystal integrity supports advanced cutting, polishing, and etching processes, achieving 15%+ yield improvement for high-end industrial silicon components.

Consistent Quality at Scale:Advanced growth control ensures axial/radial resistivity variation <5%, enabling reliable mass production of defect-free monocrystalline materials.