Provide One-stop Solutions For Si Materials

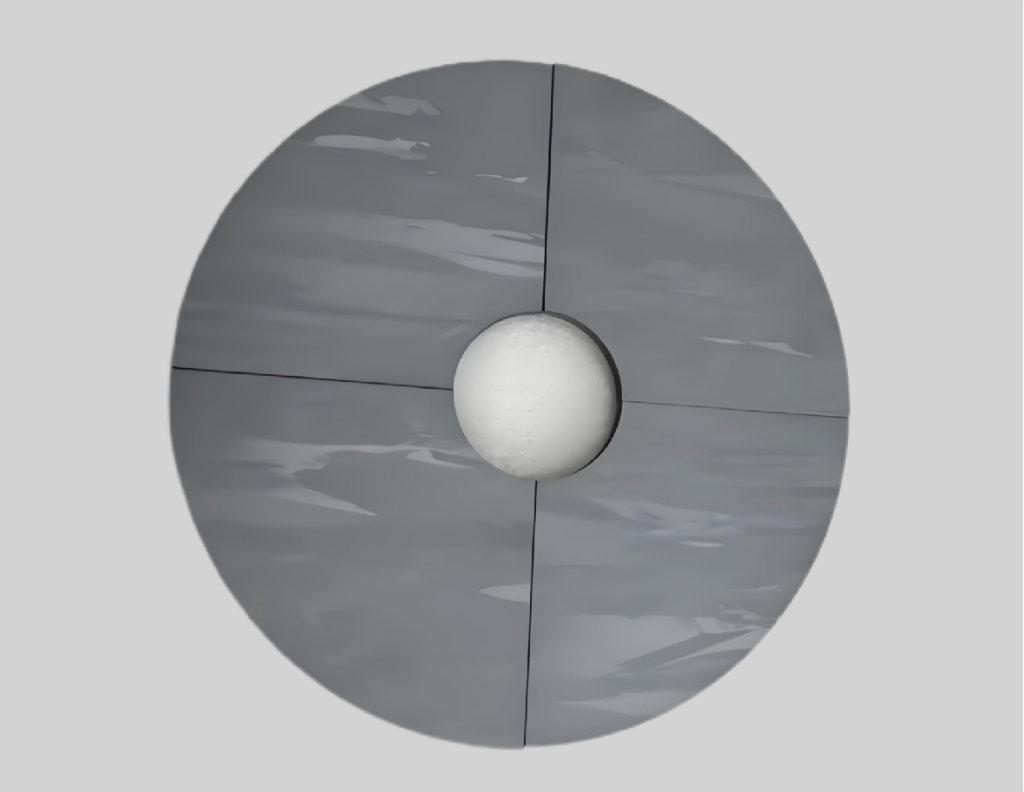

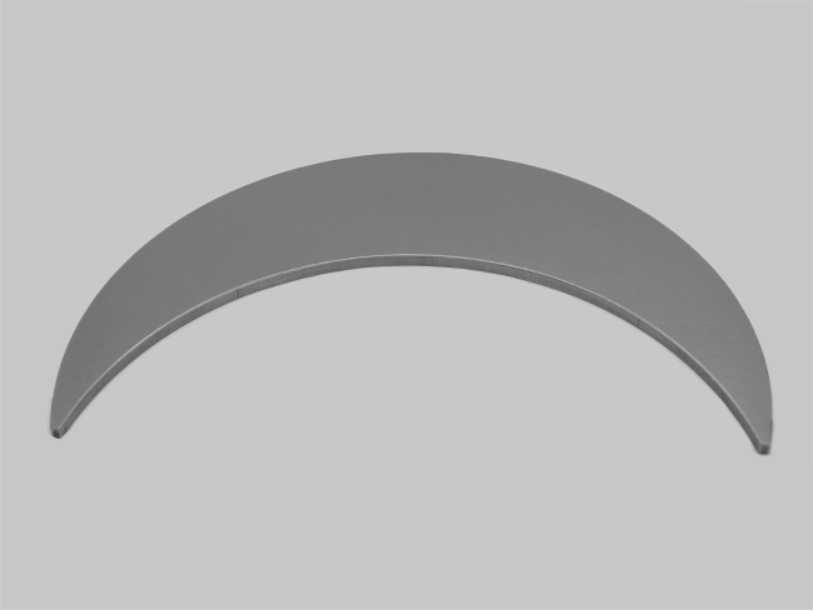

Silicon Custom-shaped Sputtering Targets are specialized materials designed for advanced thin-film deposition requiring non-conventional geometries. These targets include U-shaped, polygonal, semi-circular, and arc-shaped profiles, enabling precise coating of complex components in semiconductor, optical, and aerospace applications. Monocrystalline Silicon Targets deliver ultra-high purity (99.9999%) for nanoscale electronics, while Polycrystalline Silicon Variants offer cost-effective solutions for large-area coatings. Engineered for seamless integration with PVD/CVD systems, these targets support tailored resistivity, thermal stability, and edge-to-edge uniformity, meeting the demands of MEMS sensors, quantum devices, and high-efficiency solar cells.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >6N |

| 2 | Material | / | Mono / Poly |

| 3 | Diameter scale | mm | 0~2000 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Dopant | / | B、P、Ga、As、Sb |

| 8 | Ra | um | ≤0.8 |

Technical Advantages

Multi-Profile Flexibility (U-shape, Polygon, Arc, etc.):Coat complex 3D components seamlessly with U-shaped, polygonal, or semi-circular silicon targets, eliminating edge gaps in MEMS and optical device fabrication.

Ultra-High Purity (99.9999%) for Nanoscale Precision:Ensure defect-free thin films in quantum computing and advanced ICs using monocrystalline silicon custom geometries, certified for ISO Class 2 cleanrooms.

Thermal Stability in High-Power Sputtering:Maintain consistent deposition rates with crystalline silicon’s superior heat dissipation, reducing thermal warping by 25% versus standard alloys.

Material Efficiency via Tailored Geometry:Reduce raw material waste by 40% through non-standard target designs, optimized for curved aerospace components or microfluidic chip coatings.

Edge-to-Edge Uniformity (<1% Thickness Variation):Achieve flawless coatings on irregular surfaces with arc-shaped or polygonal targets, critical for high-efficiency solar cells and wear-resistant layers.

Dual-Process Compatibility (PVD & CVD):Accelerate R&D-to-production workflows with multi-system adaptable silicon targets, supporting both ion beam sputtering and plasma-enhanced CVD.

Rapid Prototyping for Niche Applications:From lab-scale prototypes to industrial-grade batches, deliver custom geometries (e.g., hexagonal, semi-annular) in 4-6 weeks for R&D in photonics or flexible electronics.