Provide One-stop Solutions For Si Materials

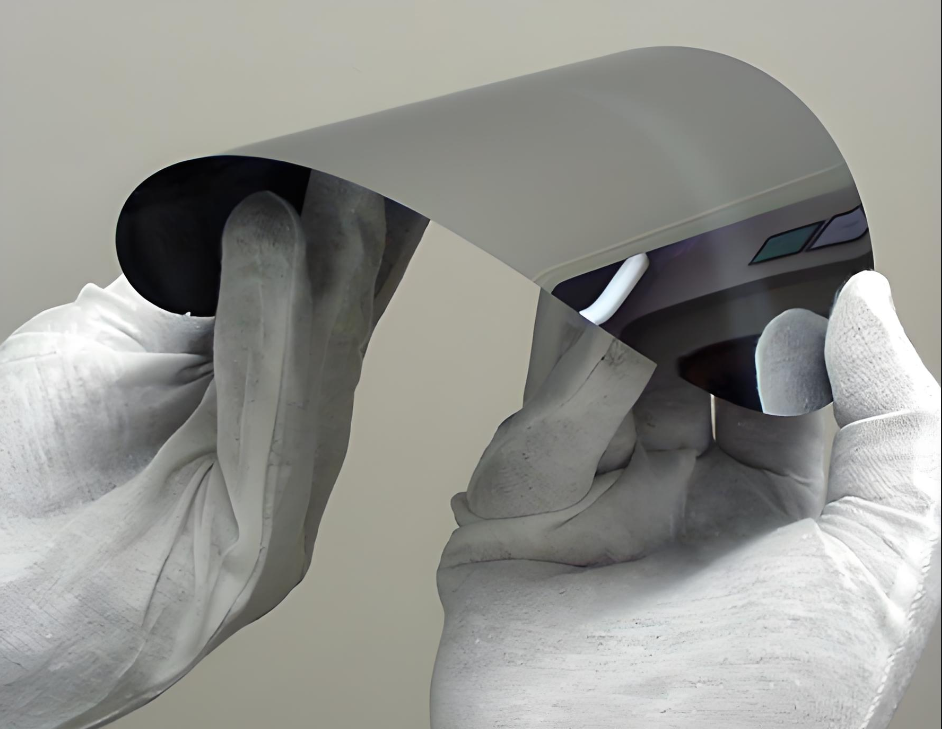

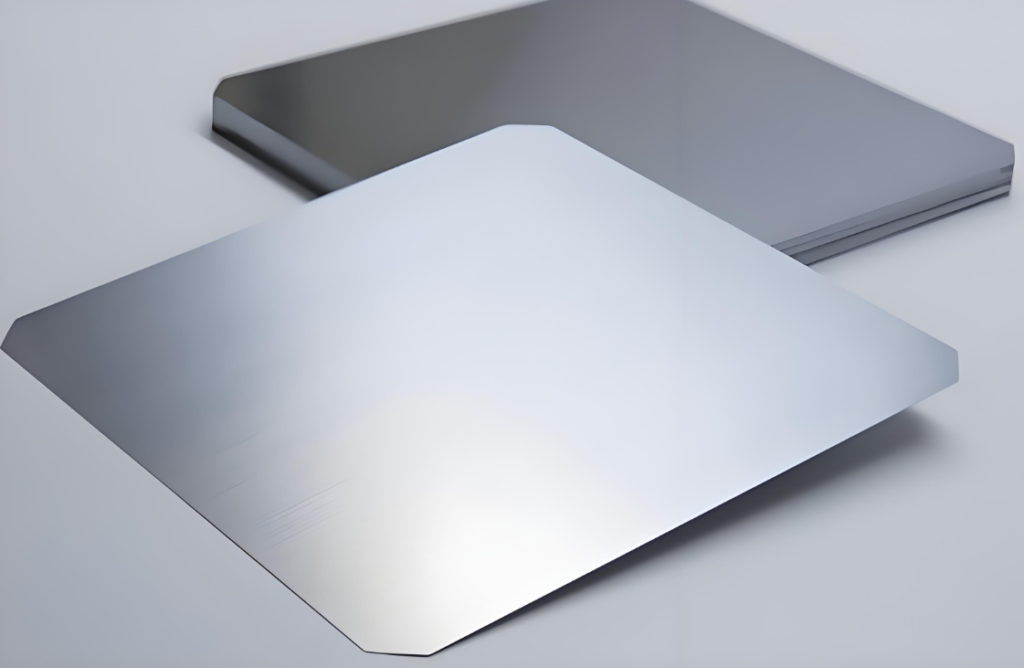

Custom silicon wafers are engineered to meet precise technical requirements for advanced semiconductor, photovoltaic, and MEMS applications. These wafers offer tailored resistivity levels (from low to high) to optimize electrical performance for specific devices. Thickness customization (ranging from ultra-thin 50μm to standard 750μm+) ensures compatibility with mechanical and thermal demands. Beyond traditional circular formats, manufacturers provide unique dimensional options, including rectangular silicon wafers for space-efficient designs and ultra-large diameter wafers (up to 450mm) to enhance production scalability. Surface finishes, crystal orientations, and edge profiles can also be adjusted, making custom wafers ideal for specialized sensors, power electronics, and cutting-edge optoelectronics systems.

- Resistivity Control: Tailored from 0.01 to 10,000 Ω-cm using advanced doping techniques (e.g., boron/phosphorus), ensuring optimal performance for logic, analog/RF, or high-voltage devices.

- Thickness Flexibility: From ultra-thin 10μm membranes for MEMS and photonics to 12mm thick substrates for power electronics, with tight tolerances down to ±1μm.

- Size & Shape Innovation: Rectangular formats (e.g., 500*500mm) and industry-leading 450mm diameters, maximizing material efficiency and reducing per-chip costs.

Technical Parameters

| Project | Content |

|---|---|

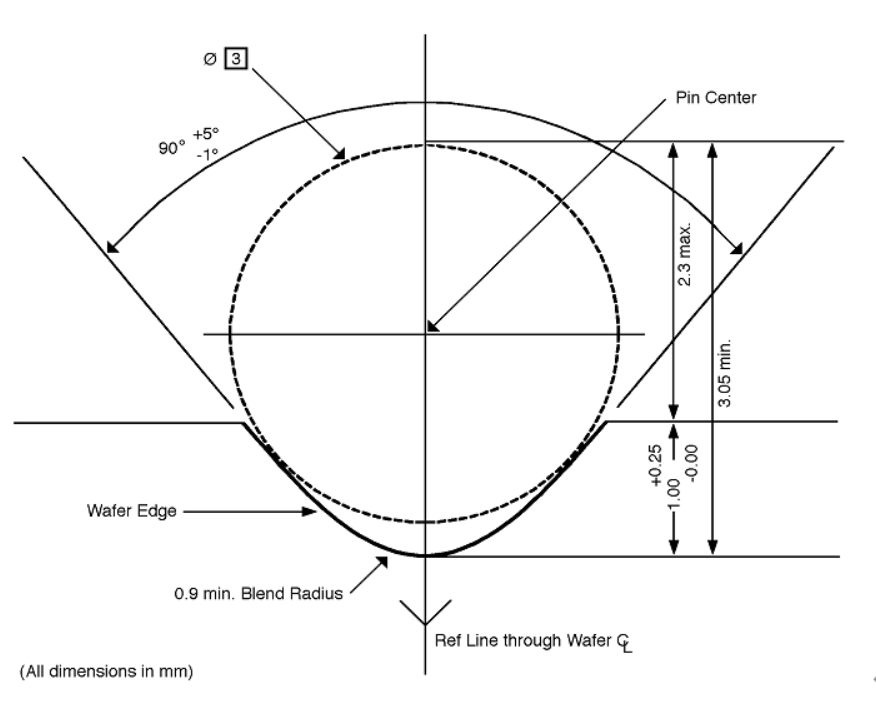

| Diameter | 2"(50.8mm)、3"(76.2mm)、4"(100mm)、5"(125mm)、6"(150mm)、8"(200mm)、12"(300mm) |

| Grade | Prime、Test、Dummy、Reclaimed |

| Growth Method | CZ、FZ |

| Orientation | 100 , 111 , 110 |

| Type/Dopant | P Type/Boron、 N Type/Phos、 N Type/As、N Type/Sb |

| Resistivity | From 0.001 to 10000 ohm-cm |

| Thickness (μm) | 50~3000μm |

| Thickness Tolerance | Standard ± 25μm、Maximum Capabilities ± 5μm |

| TTV (μm) | Standard < 10 um、Maximum Capabilities <5 um |

| Bow/Warp (μm) | Standard <40 um、Maximum Capabilities <20 um |

| Finish | As cut、Lapped、 Etched、 SSP、DSP、etc |

| Off cut | up to 7 deg |

| Particle | <10@0.5um、<10@0.3um、 <10@0.2um |

Technical Advantages

1. Precision Parameter Control for Mission-Critical Demands

- Tailored resistivity range from 0.001Ω·cm to 10,000Ω·cm, with flexible doping type (P/N) and concentration adjustments to meet diverse electrical requirements for power devices, sensors, and more.

- Thickness customization from ultra-thin 50μm to standard 1000μm, optimized for chip thinning, thermal management, or mechanical robustness.

2. Non-Standard Dimensions & Shapes to Unlock Innovation

- Deliver rectangular, trapezoidal, or ultra-large diameter (450mm+) silicon wafers, enabling compact integration or high-throughput manufacturing while minimizing material waste.

- Custom edge profiles (e.g., Notch, Flat) to enhance wafer processing compatibility and yield rates.

3. End-to-End Collaborative Development for Rapid Solutions

- Provide turnkey solutions covering crystal orientation selection (<100>/<111>/SOI), surface finishes (polished/textured), and wafer-level packaging.

- Leverage AI-driven simulation modeling + real-world testing feedback to reduce custom product development cycles by over 30%.

4. Rigorous Quality Assurance for Unmatched Consistency

- Implement laser-scanned resistivity mapping and nanoscale thickness uniformity inspection, ensuring critical parameter tolerances within ±1%