Provide One-stop Solutions For Si Materials

- Custom prototypes for R&D and testing

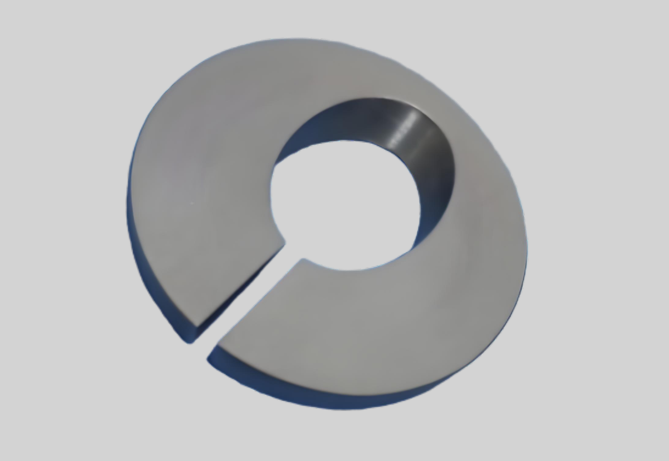

- Mass production of complex geometries

- High-temperature-resistant parts for extreme environments

- Insulated components for electronics and photonics

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >6N/9N |

| 2 | Material | / | Mono / Poly |

| 3 | Diameter scale | mm | 0~600 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Product Length | mm | 1~1000 |

| 8 | Surface treatment | / | Polishing |

Technical Advantages

Superior Thermal & Chemical Stability:CNC-machined silicon parts withstand extreme temperatures (up to 1200°C) and resist corrosion from acids, bases, and plasma environments.

Complex Geometry with Single-Crystal Integrity:Maintain crystal structure integrity during machining, enabling intricate designs for optics, sensors, and wafer processing tools.

Low Contamination & High Purity:ISO Class 7 cleanroom-compatible processes ensure minimal particulate generation, ideal for semiconductor and photonics applications.

Advanced Surface Finishing:Achieve Ra <0.1μm surface roughness for optical-grade silicon components or anti-reflective textured finishes.

Micron-Level Precision: 5-axis CNC machining ensures ±0.001mm accuracy for ultra-precise silicon components in semiconductors and medical devices.

High-Purity Material Expertise: Specialized in semiconductor-grade silicon (99.9999% purity) and advanced materials like SiC/Si₃N₄, processed in contamination-controlled environments.

Complex Geometry Capability: Handles micro-features (50μm+) and large structures (up to 500mm) via CNC milling, EDM, and laser ablation for aerospace/medical designs.