Provide One-stop Solutions For Si Materials

Float Zone (FZ) silicon wafers are advanced semiconductor materials renowned for their exceptional purity and high resistivity, making them ideal for critical applications in power electronics, RF devices, and high-efficiency solar cells. Manufactured using a crucible-free process, FZ silicon undergoes precise zone melting with radio frequency heating to minimize impurities like oxygen and carbon, achieving resistivity levels exceeding 10,000 ohm-cm. This ultra-high purity ensures superior electrical insulation and low noise performance, critical for high-power transistors, sensors, and microwave components. FZ wafers also exhibit excellent thermal stability and low defect density, enabling reliable operation in extreme environments. Available in various diameters (e.g., 2″, 3″, 4″, 6″), they serve industries demanding precision and durability, from renewable energy to aerospace. With their unique combination of high resistivity and purity, FZ silicon wafers set the standard for next-generation semiconductor solutions.

Technical Parameters

| Project | Content |

|---|---|

| Diameter | 2"(50.8mm)、3"(76.2mm)、4"(100mm)、5"(125mm)、6"(150mm)、8"(200mm)、12"(300mm) |

| Grade | Prime、Test、Dummy、Reclaimed |

| Growth Method | CZ、FZ |

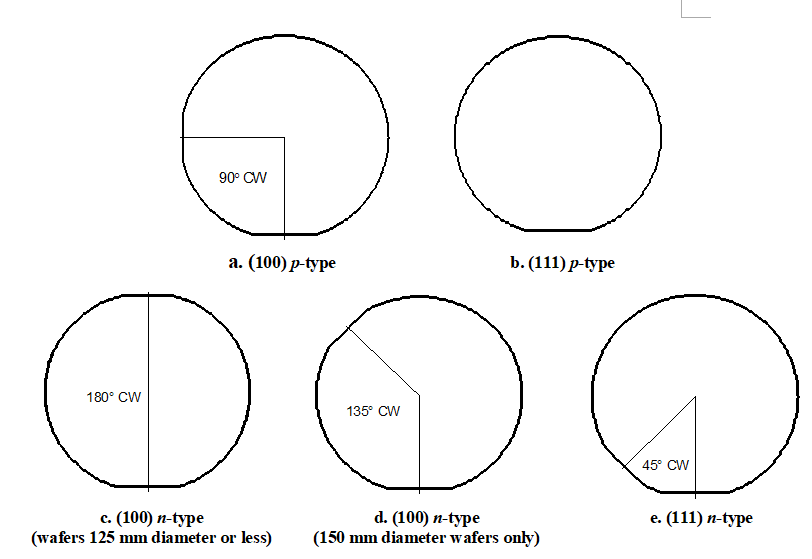

| Orientation | 100 , 111 , 110 |

| Type/Dopant | P Type/Boron、 N Type/Phos、 N Type/As、N Type/Sb |

| Resistivity | From 0.001 to 10000 ohm-cm |

| Thickness (μm) | 50~3000μm |

| Thickness Tolerance | Standard ± 25μm、Maximum Capabilities ± 5μm |

| TTV (μm) | Standard < 10 um、Maximum Capabilities <5 um |

| Bow/Warp (μm) | Standard <40 um、Maximum Capabilities <20 um |

| Finish | As cut、Lapped、 Etched、 SSP、DSP、etc |

| Off cut | up to 7 deg |

| Particle | <10@0.5um、<10@0.3um、 <10@0.2um |

Technical Advantages

Ultra-High Resistivity:Float Zone silicon wafers achieve resistivity levels exceeding 10,000 Ω·cm, enabling superior performance in high-voltage and high-frequency applications such as power devices and RF components.

Exceptional Purity:The zone melting process eliminates impurities (e.g., oxygen, carbon), achieving impurity concentrations below 1 ppb, critical for high-reliability semiconductor devices.

Low Oxygen Content (<1e16 atoms/cm³):Minimized oxygen contamination ensures stable electrical properties and reduces thermal donor formation during device processing.

Crystal Perfection with Minimal Defects:FZ-grown wafers exhibit ultra-low dislocation densities (<100 cm⁻²), enhancing carrier lifetime and device efficiency.

High Thermal Stability:Maintain structural integrity and electrical consistency even under extreme thermal processing, ideal for power MOSFETs and IGBTs.

Uniform Dopant Distribution:Precise control over dopant homogeneity ensures consistent performance across large-diameter wafers (e.g., 2-inch,4-inch,8-inch), supporting advanced semiconductor fabrication.