Provide One-stop Solutions For Si Materials

Home / Products / Quartz Part /Quartz Products

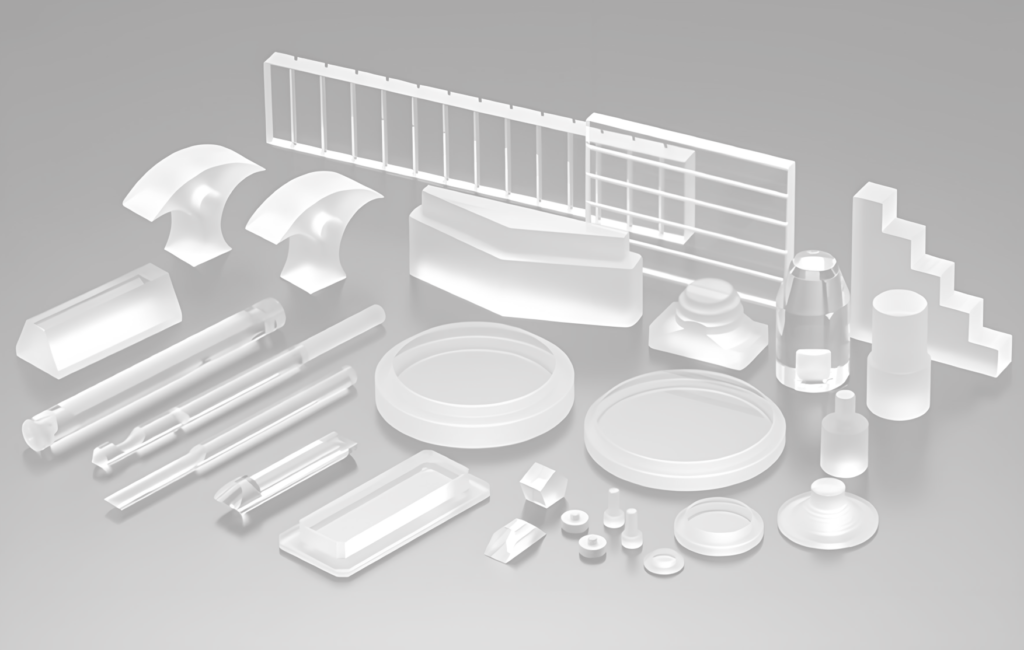

Quartz products, crafted from high-purity silicon dioxide (SiO₂), are indispensable in advanced industries due to their exceptional properties. Our precision-engineered quartz wafers, quartz boats, quartz covers, and other components offer unmatched high-temperature resistance (up to 1,730°C), chemical inertness (except to hydrofluoric acid), and optical transparency across UV to infrared spectra. Ideal for semiconductor manufacturing, they support processes like diffusion, ion implantation, and photolithography, ensuring wafer integrity in harsh environments. In photovoltaics, our quartz crucibles enable efficient silicon crystal growth, while in optics, UV-transparent quartz glass enhances laser and lighting systems. With a focus on customization and semiconductor-grade purity (99.99% SiO₂), our products meet stringent demands in electronics, aerospace, and laboratory equipment. Explore our range of durable, corrosion-resistant quartz solutions designed to elevate performance in critical applications.

Technical Parameters

| No. | Characteristic | Spec |

|---|---|---|

| 1 | Density | 2.20g/cm3 |

| 2 | Mohs hardness | 5.5~6.5 |

| 3 | Tensile strength | 4.8x10^7 Pa (N/mm2) (7000 psi) |

| 4 | Compressive strength | >1.1x10^9 Pa (160,000 psi) |

| 5 | Bulk modulus | 3.7x10^10 Pa (5.3x10^6 psi) |

| 6 | Poisson's ratio | 0.17 |

| 7 | Thermal expansion | 5.5x10^-7cm/cm.°C (20°C-320°C) |

| 8 | Thermal conductivity | 1.4 W/m.°C |

| 9 | Softening point | 1683°C |

| 10 | Annealing point | 1215°C |

| 11 | Strain point | 1120°C |

Technical Advantages

Ultra-High Purity & Chemical Stability :Crafted from semiconductor-grade raw materials with 99.99%+ SiO₂ purity, our quartz products exhibit exceptional resistance to chemical corrosion (except hydrofluoric acid), ensuring zero contamination in critical processes like semiconductor wafer cleaning or photovoltaic silicon crystal growth. Ideal for environments requiring strict purity, such as high-temperature diffusion furnaces or wet etching tanks.

Superior Thermal Performance: With a melting point of 1,730°C and low thermal expansion coefficient (0.55×10⁻⁶/°C), our quartz components maintain structural integrity in extreme temperature fluctuations, reducing thermal stress and cracking risks. Perfect for applications like rapid thermal processing (RTP) in semiconductors or high-temperature furnaces in LED manufacturing.

Precision Machining & Dimensional Accuracy: Engineered with micron-level precision (±5-10μm tolerance for quartz wafers, ±0.1mm for complex structures like quartz boats), our products meet the tightest dimensional requirements of advanced lithography and deposition equipment. Customizable shapes (flat, curved, multi-layered) and surface finishes (polished, matte, etched) ensure seamless integration into specialized systems.

- Broad Optical Transparency: Featuring 90%+ UV transmission (185-2,500nm) and high infrared transparency, our quartz glass and wafers excel in optical applications, such as UV curing systems, laser beam delivery, and spectroscopy equipment. The low hydroxyl (OH⁻) content minimizes absorption in the deep UV range, enhancing performance in lithography and analytical instruments.