Provide One-stop Solutions For Si Materials

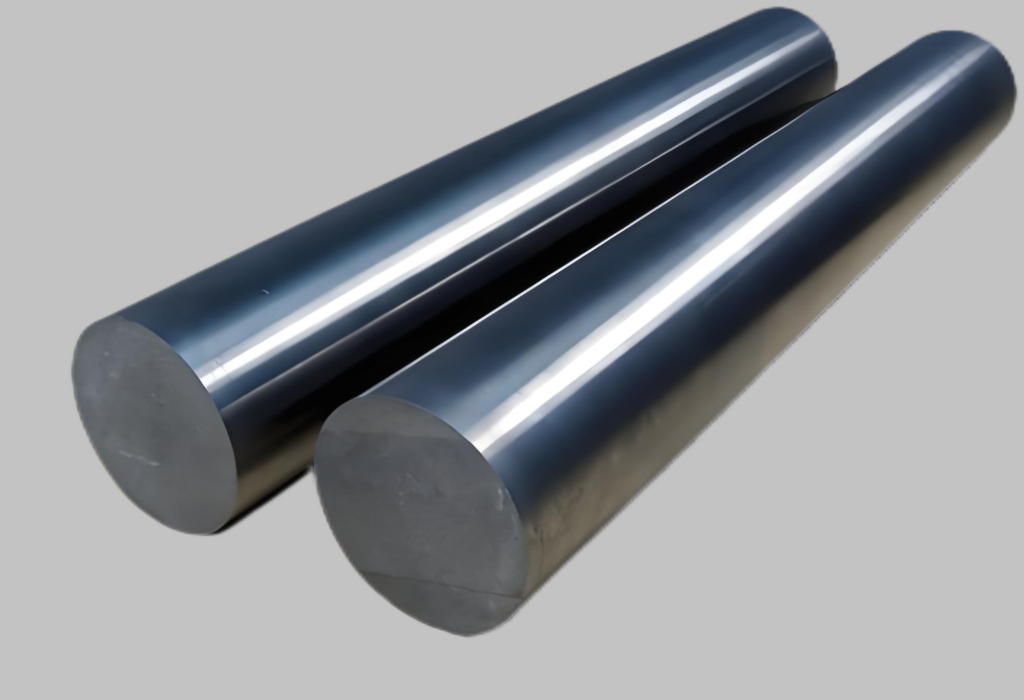

Home / Products / Si Material / FZ Silicon Rod

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >9N、11N |

| 2 | Diameter scale | mm | 0 ~ 200 |

| 3 | Type/Contains | / | Undpoed / P type / N type |

| 4 | Resistivity | Ω•cm3 | 1~300 / 300~1000 / 1000~50000 |

| 5 | Crystal Orientation | / | <100> / / |

| 6 | Oxygen saturation | ppma | <1 |

| 7 | Carbon saturation | ppma | <1 |

Technical Advantages

Poly silicon ingots can be used forprocessing large-sized silicon components and silicon target materials.The purity of silicon ingots produced by Jingge Semi can reach 6N,which is a key basic material for manufacturing semiconductor devices.

Poly silicon ingots can be processed in to large-sized silicon rings for etching purposes,as well as silicon wafers and tubes for sputtering coating purposes.

Jingge Semi full melt and semi-melt processes enable unmatched columnar grain uniformity, minimizing defects and maximizing structural integrity for high-stress applications.

Advanced refining techniques ensure ultra-low oxygen and impurity levels (<1ppb), critical for semiconductor silicon rings requiring extreme electrical stability.

Switch seamlessly between full melt (ultra-dense ingots) and semi-melt (cost-optimized batches) modes to meet diverse industry demands.

- On demands from client,Jingge Semi can make ingot in different shapes and sizes(up to 1200mm diameter).