Provide One-stop Solutions For Si Materials

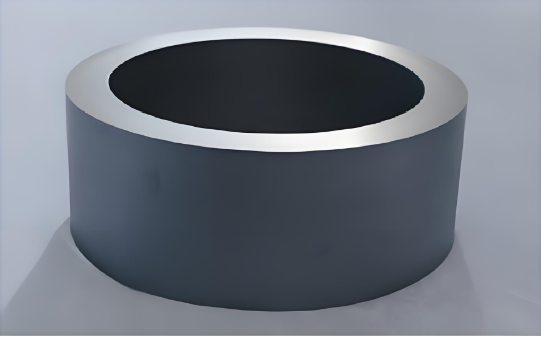

- Ultra-Precision Machining: Available in inner diameters from 1mm to 600mm with dimensional tolerances within ±0.05mm, suitable for tight-fit installations in diffusion furnaces or plasma chambers.

- High-Temperature Performance: Withstand prolonged exposure to 1200°C in oxidizing atmospheres, outperforming quartz tubes in extreme thermal cycling scenarios.

- Purity Assurance: Manufactured in ISO 8 cleanrooms to minimize particle contamination, meeting SEMI standards for semiconductor-grade components.

- Customization Options: Polished inner/outer surfaces, flanged ends, or integrated gas distribution holes for tailored applications in MEMS device fabrication or nuclear radiation detection.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >9N |

| 2 | Material | / | Mono |

| 3 | Diameter scale | mm | 0~1000 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Operating Temperature | ℃ | <1250 ℃ |

| 8 | Length | mm | 50~2000 |

Technical Advantages

Ultra-High Purity & Low Defect Density:Manufactured from electronic-grade single crystal silicon (9N purity) with impurity levels below 0.1 ppb, ensuring zero contamination in semiconductor processes and significantly improving wafer yield.

Exceptional Thermal Stability:Withstands extreme temperatures up to 1,250°C, featuring ultra-low thermal expansion coefficient (≈3×10⁻⁶/°C) and superior thermal shock resistance, ideal for rapid temperature cycling in oxidation, diffusion, and LPCVD processes.

Chemical Inertness for Process Integrity:Grain boundary-free surface eliminates side reactions with aggressive gases (e.g., Cl₂, HCl, H₂), preventing particle shedding and ensuring film uniformity (thickness variation < ±2%).

Extended Lifespan & Reduced Maintenance:Monocrystalline structure delivers outstanding creep resistance, with a service life exceeding 5,000 hours under continuous high-temperature operation, reducing downtime costs by 30%.

Compatibility with Advanced Nodes:Supports sub-3nm process technologies, meeting stringent cleanliness requirements for EUV lithography and High-k dielectric deposition, enabling mass production of cutting-edge chips.

Precise Thermal Field Control:Thermal conductivity (≈150 W/m·K) closely matches quartz, achieving furnace temperature gradients ≤1°C/cm for uniform wafer doping (RSD < 3%).

Sustainability Alignment:Compliant with SEMI F47 standards, compatible with hydrogen-based and low-carbon processes (e.g., SiH₄-Cl₂ gas mixtures), supporting semiconductor industry carbon neutrality goals.