Provide One-stop Solutions For Si Materials

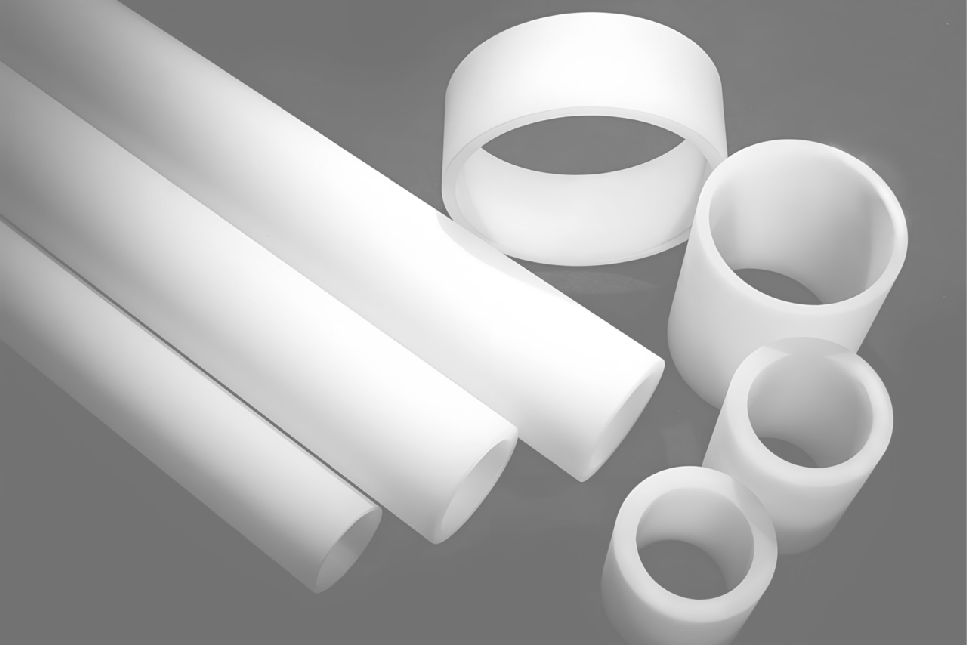

Home / Products / Quartz Part / Opaque Quartz

Technical Parameters

| No. | Characteristic | Spec |

|---|---|---|

| 1 | Density | 2.20g/cm3 |

| 2 | Mohs hardness | 5.5~6.5 |

| 3 | Tensile strength | 4.8x10^7 Pa (N/mm2) (7000 psi) |

| 4 | Compressive strength | >1.1x10^9 Pa (160,000 psi) |

| 5 | Bulk modulus | 3.7x10^10 Pa (5.3x10^6 psi) |

| 6 | Poisson's ratio | 0.17 |

| 7 | Thermal expansion | 5.5x10^-7cm/cm.°C (20°C-320°C) |

| 8 | Thermal conductivity | 1.4 W/m.°C |

| 9 | Softening point | 1683°C |

| 10 | Annealing point | 1215°C |

| 11 | Strain point | 1120°C |

Technical Advantages

Exceptional Purity & Contamination Resistance: With a SiO₂ purity exceeding 99.99%, our opaque quartz minimizes impurity migration, ensuring unmatched reliability in high-purity environments like semiconductor wafer fabrication and crystal growth processes.

Extreme Thermal Stability: Engineered to withstand continuous operating temperatures up to 1450°C with low thermal expansion (0.55×10⁻⁶/°C), our quartz resists thermal shock and maintains structural integrity in rapid heating/cooling cycles, ideal for high-temperature furnaces and solar cell manufacturing.

Superior Chemical Inertness :Highly resistant to aggressive acids, alkalis, and molten metals, our opaque quartz ensures minimal reaction with corrosive substances, making it the material for chemical processing, lab equipment, and harsh industrial environments.

Precision Engineering & Customization: Jingge Semi offer tailored solutions for complex geometries—from crucibles and tubing to precision-machined components—with tight dimensional tolerances (±0.05mm) to meet the exacting requirements of your application.

Enhanced Mechanical Durability: Jingge arc-melted opaque quartz features a dense microstructure, delivering superior impact and abrasion resistance compared to standard ceramics, reducing downtime and maintenance costs in heavy-duty industrial use.

Consistent Performance Across Industries :Trusted in critical applications such as semiconductor wafer production, solar photovoltaic manufacturing, and high-temperature research, our quartz guarantees uniform quality batch after batch, backed by rigorous material testing and ISO 9001 certification.