Provide One-stop Solutions For Si Materials

Silicon Optical Windows are high-performance infrared-transmitting components widely used in thermal imaging, spectroscopy, and laser systems. Made from high-purity monocrystalline silicon, these windows exhibit exceptional transmittance in the 1.2-7 μm infrared spectrum, making them ideal for CO2 laser applications (10.6 μm) and MWIR/LWIR detection. Key advantages include low thermal expansion, high chemical resistance, and compatibility with harsh environments. Customizable with AR coatings or diamond-like carbon (DLC) layers, silicon windows optimize transmission efficiency while minimizing surface reflection. As critical components in aerospace, defense, and industrial sensing, they balance cost-effectiveness with durability for demanding optical systems.

Silicon mirrors are high-precision optical components widely used in laser systems, astronomy, and semiconductor manufacturing due to their exceptional reflectivity (up to 99.8% for CO₂ lasers) and thermal stability. Crafted from single crystal silicon or polycrystalline silicon, these mirrors undergo precision machining and advanced coatings (e.g., gold, dielectric) to optimize performance across wavelengths from infrared to UV. Their low thermal expansion coefficient ensures stability in extreme temperature variations, while lightweight designs (e.g., BSOI technology) make them ideal for aerospace and scanning applications. Whether used as resonator mirrors in lasers, X-ray telescopes, or high-speed scanning arrays, silicon mirrors deliver unmatched durability and optical accuracy, making them a cornerstone of modern photonics.

Silicon Optical Lenses are advanced infrared (IR) optics widely used in thermal imaging, laser systems, and aerospace applications. Made from high-purity silicon (Si), these lenses offer exceptional transmission in the 1.2–7 μm wavelength range, making them ideal for MWIR and LWIR technologies. Key advantages include high thermal stability, resistance to harsh environments, and compatibility with anti-reflective coatings for enhanced performance.

Concave Silicon Lenses: Designed for beam divergence, collimation, and correcting optical aberrations in IR systems.

Convex Silicon Lenses: Optimized for light focusing, magnification, and high-power laser applications.

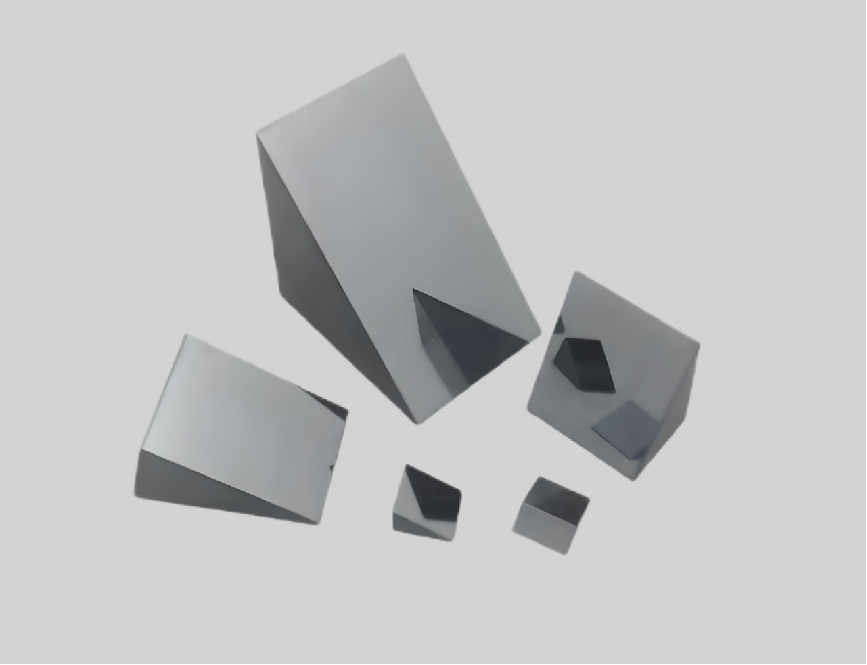

Silicon prisms are precision optical components widely used in infrared (IR) systems, laser technologies, and spectroscopy due to their exceptional thermal stability and high refractive index in the IR spectrum. Manufactured from high-purity monocrystalline silicon, these prisms exhibit low optical absorption and superior durability in extreme environments, making them ideal for applications such as thermal imaging, scientific instrumentation, and industrial laser beam steering. Custom silicon prism manufacturing allows tailored designs to meet specific wavelength requirements, while their compatibility with advanced coatings enhances performance in complex optical setups. As a critical element in modern optoelectronics, silicon prisms combine material efficiency with engineering versatility, supporting innovations in both research and industrial sectors.

Jingge Semi’s silicon galvanometer, also known as a MEMS (Micro-Electro-Mechanical Systems) scanning mirror, is a miniaturized optical device fabricated from silicon-based materials. It utilizes MEMS technology to achieve high-speed and precise angular deflection, enabling applications in laser beam steering, optical communication systems, LiDAR, and biomedical imaging. Key advantages include ultra-fast response time (microsecond-level), low power consumption, and exceptional thermal stability. These mirrors are critical components in advanced technologies such as augmented reality (AR) displays, laser projectors, and adaptive optics, offering scalable solutions for industries requiring compact, high-performance optical control.