Provide One-stop Solutions For Si Materials

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >6N/9N |

| 2 | Material | / | Mono / Poly |

| 3 | Diameter scale | mm | 0~600 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Product Length | mm | 1~1000 |

| 8 | Surface treatment | / | Polishing |

Technical Advantages

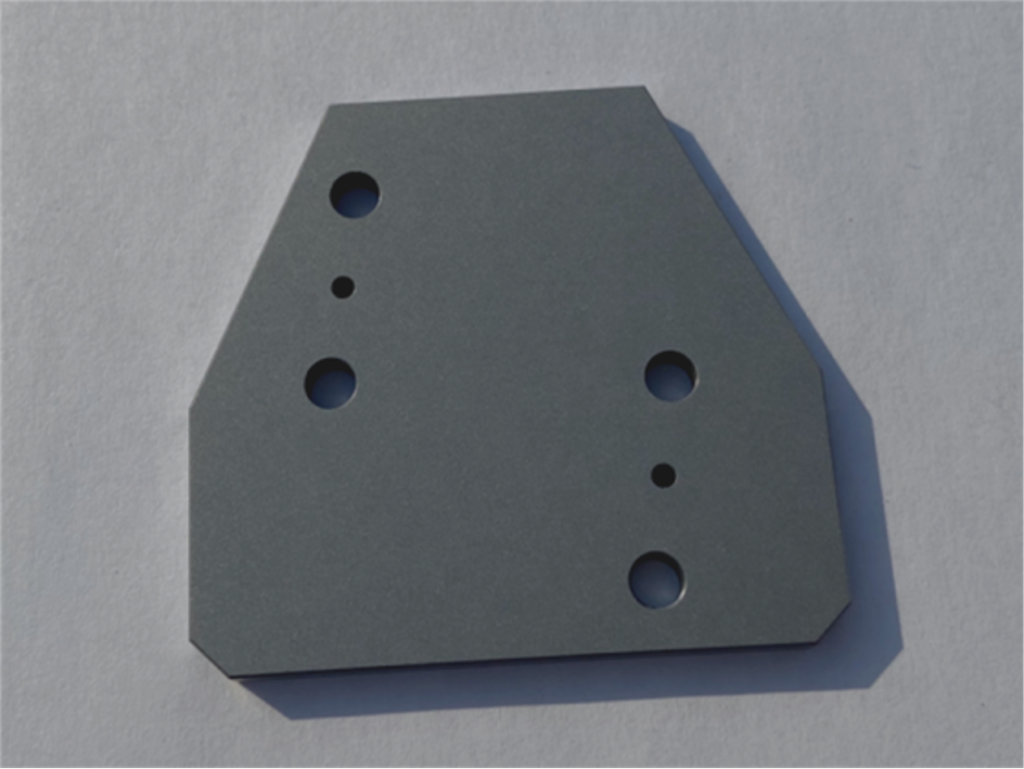

Advanced Laser Drilling Technology:Achieve micron-level precision with minimal thermal damage, ensuring flawless micro-hole patterns for critical applications.

Micron-Level Accuracy for High-Density Arrays:Consistent hole diameters (from 5µm to 50mm) , ideal for MEMS, photonics, and sensor integration.

Superior Material Integrity:High-purity monocrystalline silicon substrates maintain exceptional thermal stability (up to 1200°C) and electrical performance.

Custom Design Flexibility:Tailor hole geometry, pitch, and patterns (hexagonal, radial, or random) to meet your unique R&D or production requirements.

Multi-Layer Compatibility:Seamlessly integrate with thin-film coatings, metallization, and hybrid bonding processes for advanced semiconductor devices.

Rapid Prototyping & Scalable Production:From small-batch R&D samples to high-volume orders, deliver industry-leading turnaround times without compromising quality.

Enabling Next-Gen Innovations:Power breakthroughs in quantum computing, microfluidics, and optical systems with ultra-precise perforated silicon solutions.