Provide One-stop Solutions For Si Materials

Polycrystalline Silicon Tubes are essential components in high-temperature industrial processes, particularly in semiconductor manufacturing and photovoltaic (PV) production. Composed of aggregated small silicon crystals, these tubes exhibit excellent thermal stability (withstanding temperatures up to 1,250°C) and chemical inertness, making them ideal for applications such as chemical vapor deposition (CVD), diffusion, and oxidation processes in semiconductor furnace systems.

In semiconductor fabrication, polycrystalline silicon tubes are widely used in LPCVD (Low-Pressure Chemical Vapor Deposition) systems to deposit uniform thin films (e.g., polysilicon gate electrodes) on wafers, ensuring precise control over electrical properties and device performance36. Their high purity (typically solar-grade 6N or electronic-grade 11N) minimizes contamination risks in sensitive processes like transistor and integrated circuit (IC) manufacturing.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >9N |

| 2 | Material | / | Mono |

| 3 | Diameter scale | mm | 0~1000 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Operating Temperature | ℃ | <1250 ℃ |

| 8 | Length | mm | 50~2000 |

Technical Advantages

Cost-Effective High-Performance Material:Engineered with electronic-grade polycrystalline silicon, balancing purity and affordability for large-scale semiconductor and photovoltaic production.

Superior Thermal Uniformity:Maintains stable performance at temperatures up to 1,200°C, with optimized grain structure minimizing thermal stress during rapid CVD or diffusion processes.

Enhanced Chemical Resistance:Resists corrosion from aggressive gases (e.g., HCl, Cl₂, H₂) and dopants, ensuring consistent process integrity in epitaxial growth and thin-film deposition.

High Durability in Harsh Environments:Robust polycrystalline structure reduces crack propagation risk, delivering a service life of4,000+ hours in continuous high-temperature furnace operations.

Scalable for Mass Production:Ideal for fluidized bed reactors (FBR) and Modified Siemens Process, enabling efficient production of granular polysilicon for solar cells and semiconductor ingots.

Versatile Thin-Film Applications:Enables uniform LPCVD polysilicon layers with thickness precision (±3%), critical for gate electrodes in logic chips and passivation layers in TOPCon solar cells.

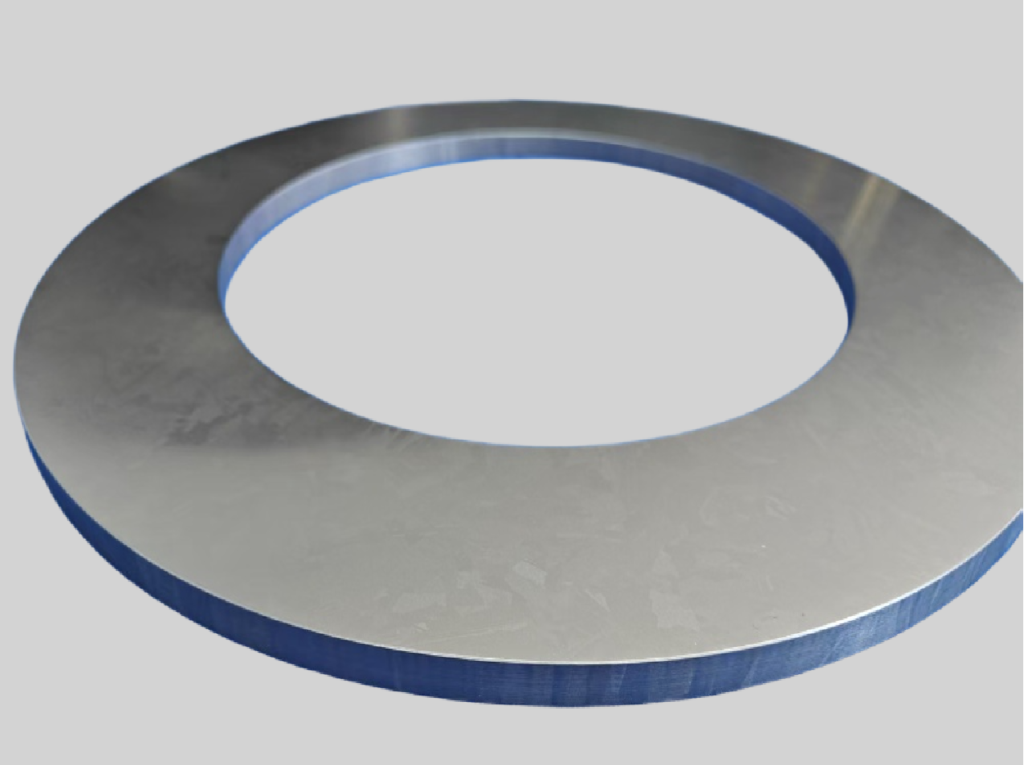

Advanced Machinability for Critical Components:Serves as a premium raw material for polysilicon exhaust rings, offering high-purity, corrosion-resistant blanks for precision machining of semiconductor etching parts (e.g., gas distribution rings, plasma etch shields).