Provide One-stop Solutions For Si Materials

Home / Products / Quartz Part / Quartz Rod&Ingot

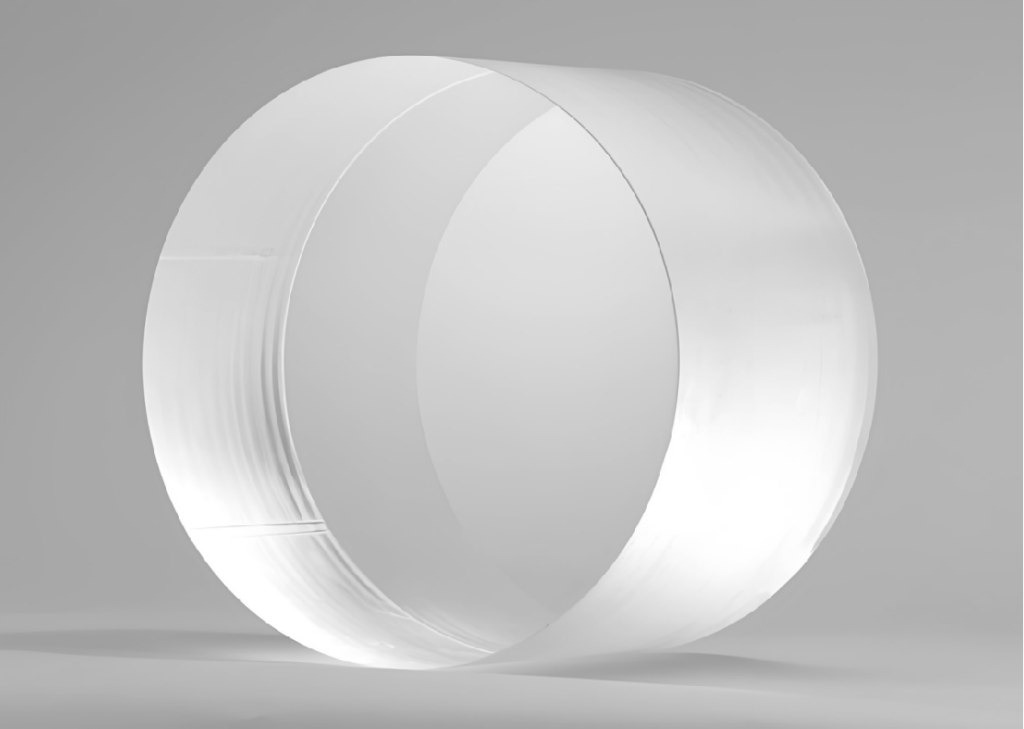

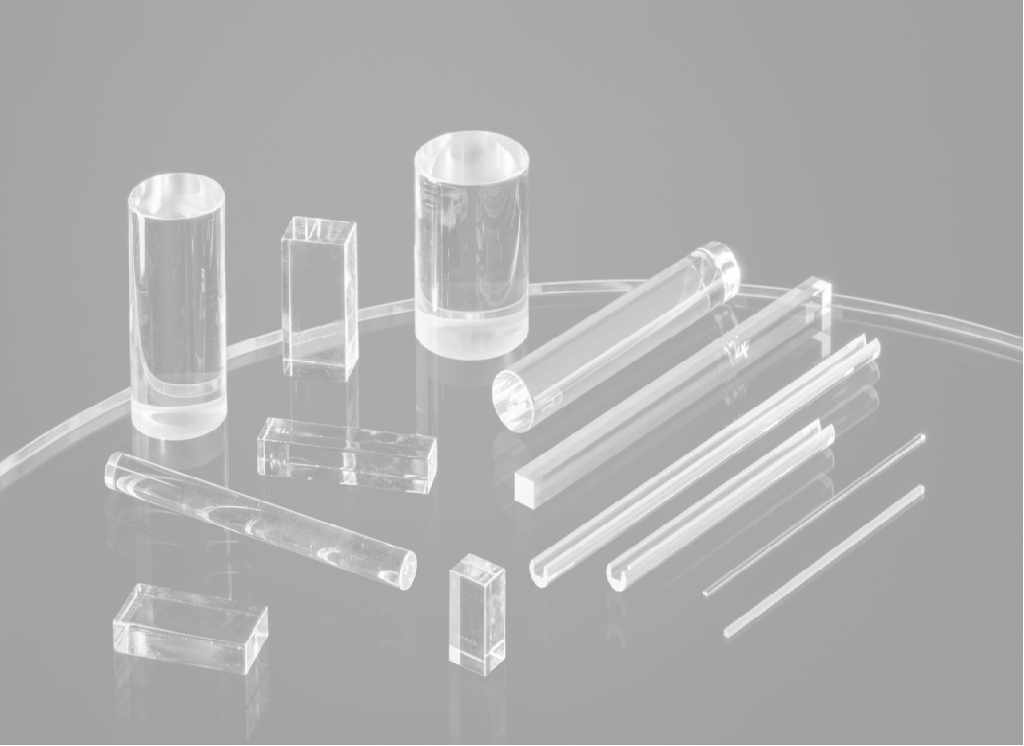

Jingge Semi optical quartz ingots or rods, crafted from 99.99%+ pure fused silica (SiO₂), are engineered to deliver unparalleled performance in high-precision applications. These ingots exhibit ultra-low thermal expansion (5.5×10⁻⁷/K), ensuring dimensional stability during rapid temperature fluctuations up to 1200°C29. Their superior UV transmittance (≥90% in the 200–400 nm range) and low hydroxyl content (0.5–1000 ppm) make them ideal for semiconductor photomask substrates, laser optics, and UV curing systems.

Customizable dimensions: Available in diameters from 1 mm to 200 mm, tailored for specific industrial requirements.

Superior material properties: High chemical stability and resistance to thermal shock, ideal for extreme environments.

Certified quality: ISO-compliant production processes ensure consistency for applications like photolithography and spectroscopy.

Technical Parameters

| No. | Characteristic | Spec |

|---|---|---|

| 1 | Density | 2.20g/cm3 |

| 2 | Mohs hardness | 5.5~6.5 |

| 3 | Tensile strength | 4.8x10^7 Pa (N/mm2) (7000 psi) |

| 4 | Compressive strength | >1.1x10^9 Pa (160,000 psi) |

| 5 | Bulk modulus | 3.7x10^10 Pa (5.3x10^6 psi) |

| 6 | Poisson's ratio | 0.17 |

| 7 | Thermal expansion | 5.5x10^-7cm/cm.°C (20°C-320°C) |

| 8 | Thermal conductivity | 1.4 W/m.°C |

| 9 | Softening point | 1683°C |

| 10 | Annealing point | 1215°C |

| 11 | Strain point | 1120°C |

Technical Advantages

Ultra-High Purity Engineering:Crafted from 99.95%+ SiO₂ fused silica, our products minimize metal impurities (<0.01 ppm), ensuring unmatched chemical stability and reliability in critical applications like semiconductor manufacturing and UV optics.

Extreme Thermal Resilience:Withstands continuous operating temperatures up to 1200°C and rapid thermal cycling (ΔT ≤ 800°C/hr) thanks to ultra-low thermal expansion (5.5×10⁻⁷/K), delivering superior dimensional stability in high-heat environments.

Optical Excellence:Achieves ≥94% UV transmittance (200–400 nm) and <0.1% total integrated scatter (TIS), ideal for precision optical systems, laser components, and UV curing where clarity and light efficiency are non-negotiable.

Customizable to Your Specs:Available in diameters from 1 mm to 400 mm and lengths up to 4000 mm, with adjustable hydroxyl content (0.5–1000 ppm) and surface finishes (polished/ground) to meet exacting project requirements.

Corrosion-Resistant Durability:Highly resistant to acids (except HF) and alkali environments, extending service life in aggressive chemical processing, medical device sterilization, and solar panel production.

- Precision Engineering for Next-Gen Tech:Engineered with ≤5 μm internal defect density and <0.05% bubble inclusion, providing the structural integrity required for advanced applications like photomask substrates and high-power laser tubes.