Provide One-stop Solutions For Si Materials

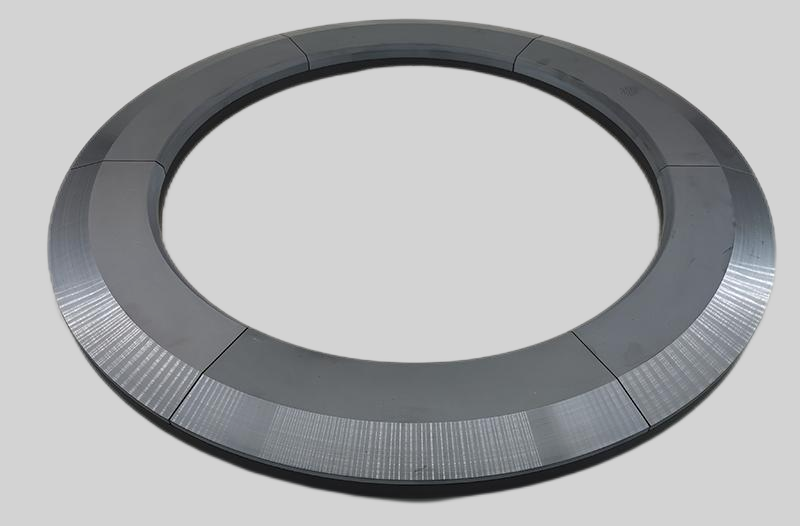

- Plasma Confinement: By generating an electric field around the wafer perimeter, silicon focus rings direct plasma ions toward the target area, reducing etch non-uniformity caused by plasma diffusion.

- Edge Protection: Their concave or stepped design shields the wafer’s edge from excessive plasma bombardment, preventing damage during high-energy etching.

- Material Compatibility: High-purity silicon variants resist corrosion from fluorine-based etchants (e.g., SF₆), while SiC-coated rings withstand extreme temperatures (up to 1400°C) and corrosive environments.

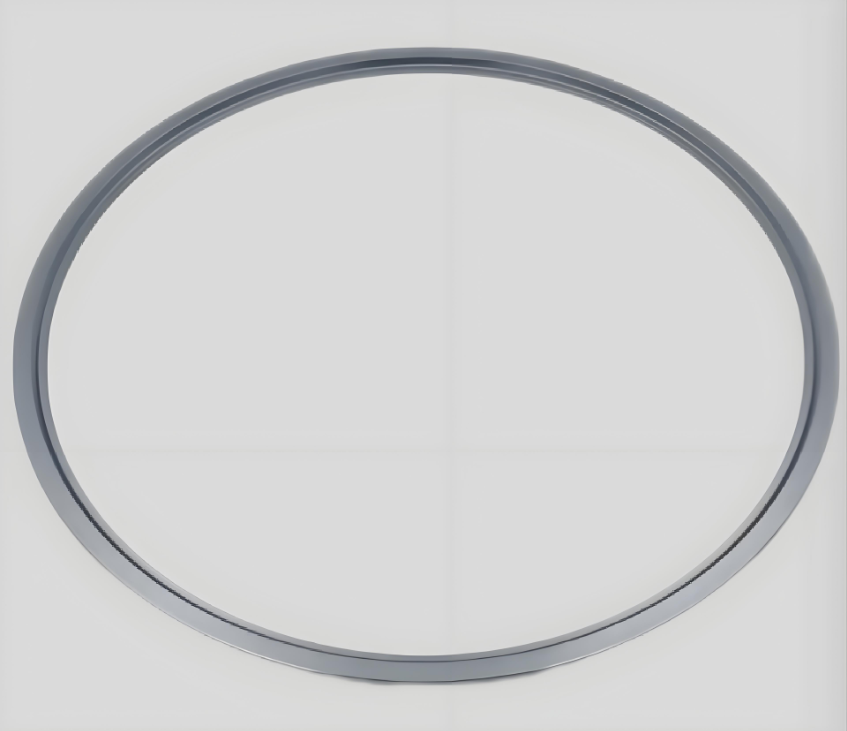

- Customization: Available in diameters from 8″ to 12″ (200–300mm), with options like vacuum channels for secure wafer clamping and anti-static surfaces to mitigate particle contamination.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >6N |

| 2 | Material | / | Mono / Poly |

| 3 | Diameter scale | mm | 0~500 / Customizable |

| 4 | Type/Contains | / | P type / N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Dopant | / | B、P、Ga、As、Sb |

| 8 | Surface treatment | / | Polishing |

Technical Advantages

High-Purity Silicon (99.99999%):Engineered with contamination-free material to eliminate wafer edge defects in ultra-sensitive EUV and high-k dielectric etching processes.

Extreme Plasma & Chemical Resistance:Withstands corrosive plasmas (Cl₂, O₂, HBr) and thermal cycling up to 750°C, ensuring 20,000+ process cycles without degradation.

Edge Etch Uniformity Control:Precision-machined geometry reduces edge exclusion zones to <1mm and achieves ±1% etch rate uniformity across 300mm wafers.

Multi-Frequency RF Compatibility:Optimized dielectric properties ensure stable plasma coupling under 2MHz-60MHz RF ranges, critical for advanced 3D NAND and GAA transistor fabrication.

Low-Particle Surface (Ra <0.2nm):Atomic-level polishing minimizes micro-arcing and particle adhesion, improving overall wafer yield to >99.97%.