Provide One-stop Solutions For Si Materials

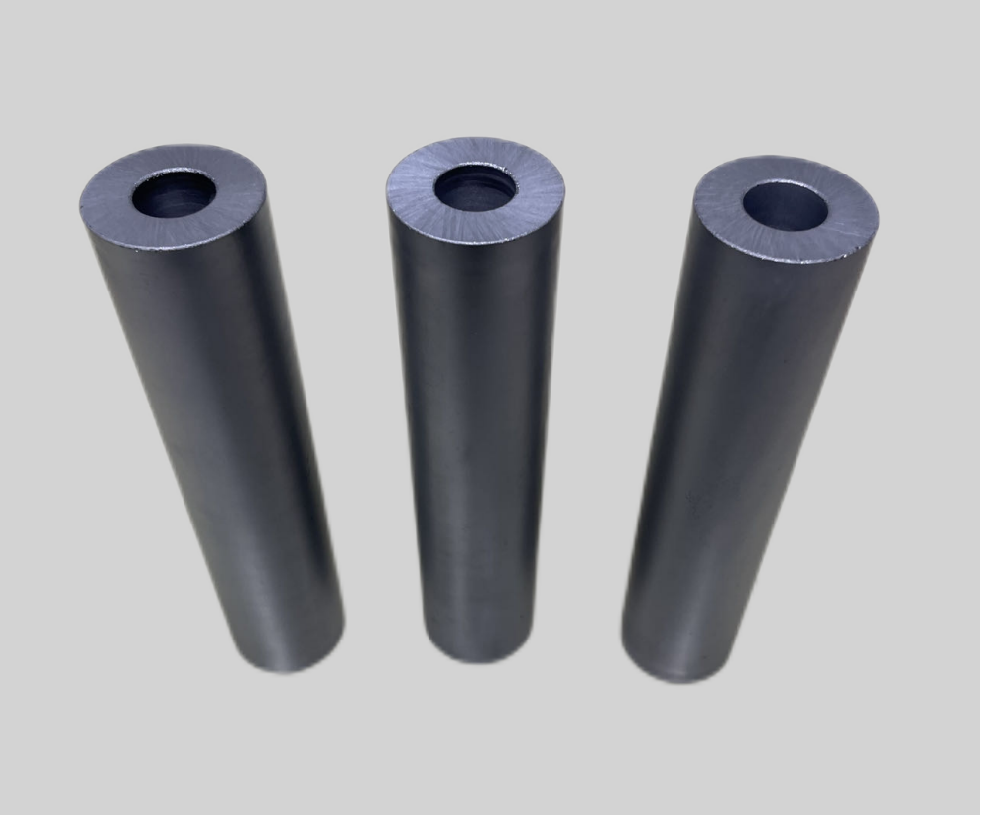

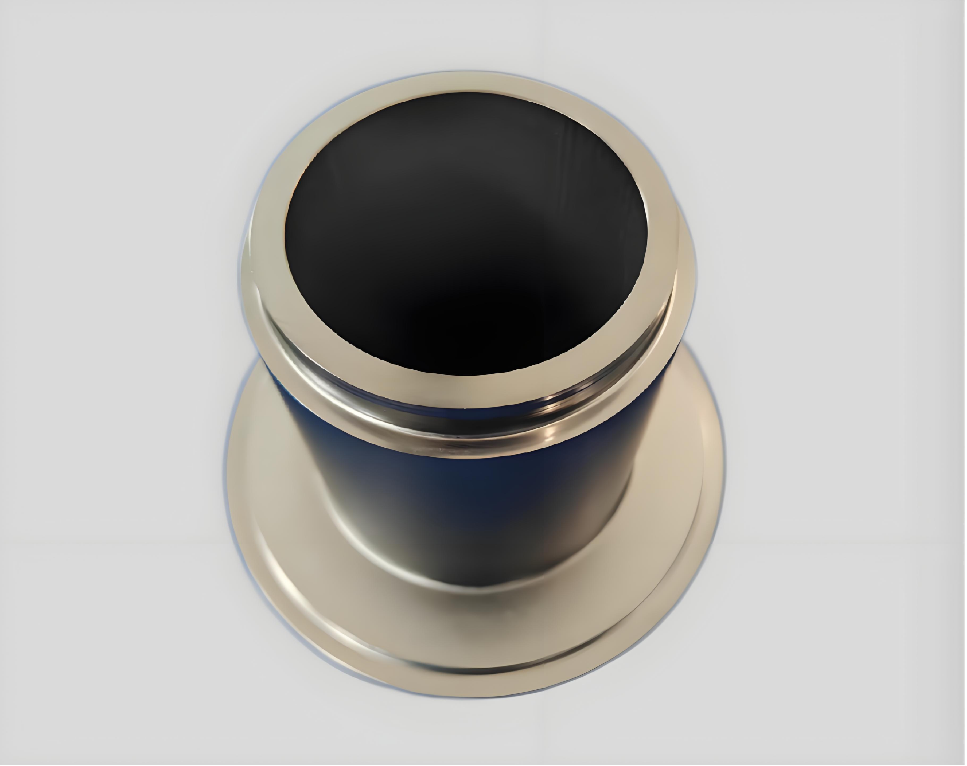

Silicon lined tubes are advanced industrial components designed to maintain product integrity in critical applications. Crafted from ultra-pure silicon (≥99.9999%), these liners act as a protective barrier against chemical corrosion, particle contamination, and thermal degradation. Their non-reactive surface ensures zero leaching or interaction with sensitive fluids, making them ideal for industries like semiconductor manufacturing, pharmaceuticals, and food processing.

Purity Assurance: Silicon’s inherent non-reactive nature ensures no metallic leaching or impurities, maintaining product integrity in sensitive environments like wafer manufacturing or drug synthesis.

Thermal and Chemical Resistance: Withstanding extreme temperatures (up to 1200°C) and aggressive chemicals (acids, alkalis), silicon liners are ideal for applications in chemical vapor deposition (CVD) reactors and corrosive fluid transport.

Smooth Surface Properties: The atomic-level smoothness of silicon reduces particle adhesion, minimizing contamination risks in high-precision processes.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >9N |

| 2 | Material | / | Mono / Poly |

| 3 | Diameter scale | mm | 0~1000 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Operating Temperature | ℃ | <1250 ℃ |

| 8 | Length | mm | 50~2000 |

Technical Advantages

Ultra-High Purity (99.9999%):Non-reactive silicon lining ensures zero metallic contamination, critical for semiconductor and pharmaceutical industries.

Superior Thermal Stability (Up to 1200°C):Maintains structural integrity in extreme heat, ideal for CVD reactors and high-temperature processing.

Exceptional Chemical Resistance:Resists corrosion from acids, alkalis, and aggressive solvents, ensuring long-term durability.

Low-Particle Adhesion Surface:Atomically smooth silicon layer minimizes particle retention, reducing contamination risks.

Chemical Inertness:Prevents unwanted reactions with sensitive materials, preserving product quality in labs and production lines.

Customizable Designs:Tailored dimensions and coatings to meet specific process requirements (e.g., gas delivery, fluid transfer).

Semiconductor-Grade Certification:Complies with stringent industry standards (e.g., SEMI, ISO) for ultra-clean manufacturing environments.