Provide One-stop Solutions For Si Materials

Home / Products / Si Optical / Silicon mirrors

Silicon mirrors are precision-engineered optical components designed for high-performance applications requiring exceptional reflectivity and thermal stability. Manufactured from high-purity silicon substrates, these mirrors are coated with advanced dielectric or metallic layers to achieve reflectance rates exceeding 99% across a broad wavelength spectrum, including ultraviolet (UV), visible, and infrared (IR) ranges. Their low thermal expansion coefficient and resistance to environmental degradation make them ideal for demanding environments such as aerospace, laser systems, and astronomical telescopes.

Laser Technology: Custom silicon mirrors optimize beam steering in high-power laser setups.

Spectroscopy: Durable coatings ensure minimal signal loss in analytical instruments.

Space Optics: Silicon’s lightweight properties enhance satellite and telescope mirror designs.

Technical Parameters

| Optical Properties | |

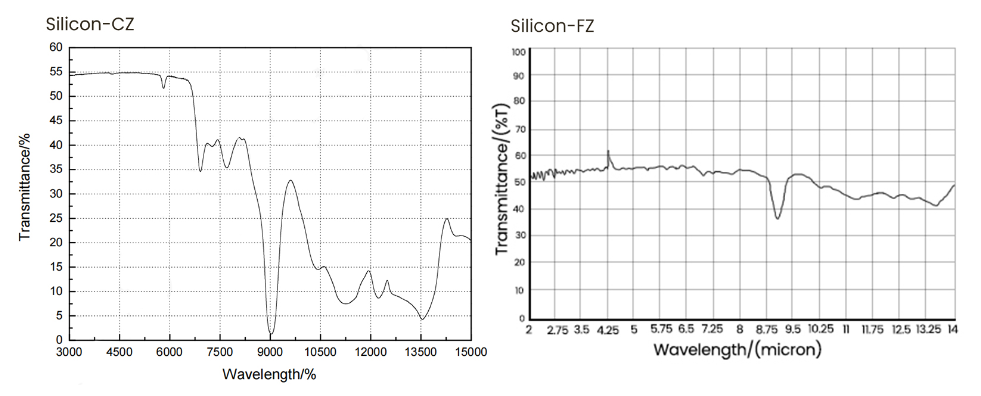

| Transmission Range | 1.2-15μm |

| Refractive Index | 3.41776%@10μm |

| Reflection Loss | 46.1%@10μm |

| Structure | Single crystal,synthetic |

| Cleavage Planes | <111> |

| Physical Properties | |

| Density[g/cm3] | 2.33 |

| Melting Point [℃] | 1414 |

| ThermalConductivity [W/(m×K)] | 163 @ 313K |

| Thermal Expansion [10-6/K] | 2.6 @ 293K |

| Knoop Hardness [kg/mm2] | 1100 |

| Specific Heat Capacity [J/(kg×K)] | 712.8 |

| Dielectric Constant | 13 @f= 9.37GHz |

| Young’s Modulus (E) [GPa] | 130.91 |

| Shear Modulus(G) [GPa] | 79.92 |

| Bulk modulus(K) [GPa] | 101.97 |

| Poisson Coefficient | 0.266 |

| Chemical Properties | |

| Solubility / g/L | None |

| Molecular Weight / g/mol | 28.09 |

| Project | Specification |

|---|---|

| Size range | 2-300mm |

| Thickness | 0.12-60mm |

| Finish | 80-50,60-40,40-20,20-10,10-5 |

| Face | λ/2,λ/4,λ/8,λ/10 |

| Parallelism | <3'-30” |

| Clear aperture | >90% |

Technical Advantages

Ultra-High Reflectivity:Multi-layer nano-coating technology ensures >99% reflectance across UV-Vis-IR spectra, maximizing light efficiency for laser systems and spectroscopic instruments.

Superior Thermal Stability:Ultra-low thermal expansion coefficient (CTE <3×10⁻⁶/K) minimizes surface deformation (<λ/10) under extreme temperatures (-50°C to +300°C), ideal for aerospace and space optics.

Nanoscale Surface Precision:Ultra-smooth surface finish (<0.5 nm RMS) reduces scattering losses, critical for UV laser applications and quantum computing optics.

High Laser Damage Threshold:Ion Beam-Assisted Deposition (IBAD) coatings withstand >10 kW/cm² laser power with zero delamination, ensuring longevity in high-power industrial lasers.

Lightweight & Durable Design:Silicon substrates offer 1/3 the weight of traditional metal mirrors, paired with honeycomb structures for aerospace-grade strength-to-weight ratios.

Customization Flexibility:Rapid prototyping of aspheric shapes, multi-wavelength coatings, and bespoke apertures (4-week lead time), tailored for telescopes, medical imaging, and micro-optics.