Provide One-stop Solutions For Si Materials

- Material expertise: Single crystal silicon’s low thermal expansion and high thermal conductivity make it ideal for extreme environments.

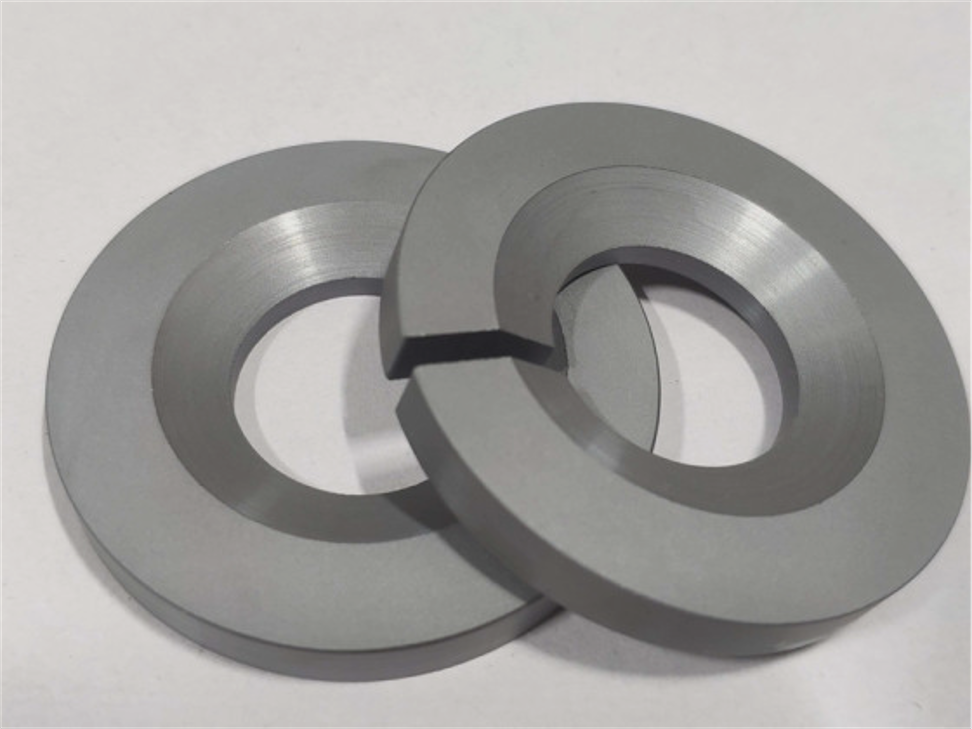

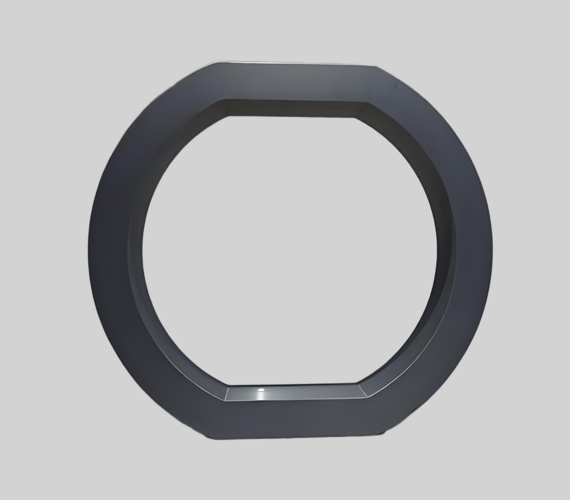

- Customization: From complex geometries to microstructures, we accommodate prototypes to mass production.

- Quality assurance: ISO-certified processes and particle-free cleanroom environments ensure defect-free results.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >6N/9N |

| 2 | Material | / | Mono / Poly |

| 3 | Diameter scale | mm | 0~600 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | (100)、(111)、(110) |

| 7 | Product Length | mm | 1~1000 |

| 8 | Surface treatment | / | Polishing |

Technical Advantages

Sub-Micron Precision Machining

Advanced CNC with diamond tooling achieves ≤±1μm tolerance for mission-critical semiconductor tooling.Micro-Threading Expertise

M0.5+ micro-threads (internal/external) with Ra<0.1μm roughness, ideal for ultra-high vacuum systems.Zero Micro-Crack Guarantee

Proprietary stress-relief protocols eliminate microfractures, validated by 100% microscopic inspection.3D Complex Geometry Fabrication

5-axis machining enables 0.05mm minimal feature size for non-standard optical/mechanical interfaces.High-Purity Material Integrity

Cleanroom processing preserves 99.9999% crystalline silicon purity (ASTM F57 compliant).Thermal-Stable Performance

Post-machining annealing (up to 1200°C) ensures <0.01% dimensional deviation under extreme thermal cycling.