Provide One-stop Solutions For Si Materials

Home / Products / Si Material

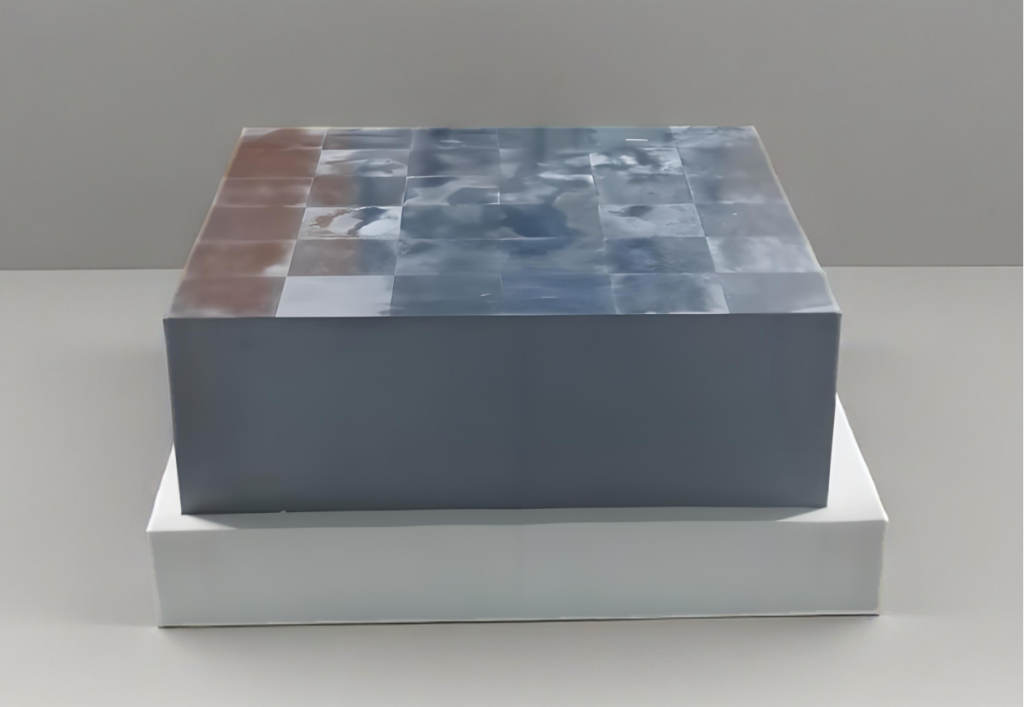

Polycrystalline Silicon Ingot zhe key for Semiconductor Etching. With a high purity of up to 99.9999%, is crucial in the semiconductor industry for etching components. Made via a directional solidification process, it features uniform columnar grains, a significant advantage.introduce relatively low nitrogen impurities.

This casting silicon ingot method is cost-effective and efficient in material utilization. The high purity reduces impurities that could disrupt the etching process, while the grain uniformity ensures consistent properties for precise etching.

Directional solidification enhances crystal quality, minimizing defects. Combined with its high purity, our polycrystalline silicon ingots meet strict semiconductor standards, offering reliability and precision for high-quality device production.

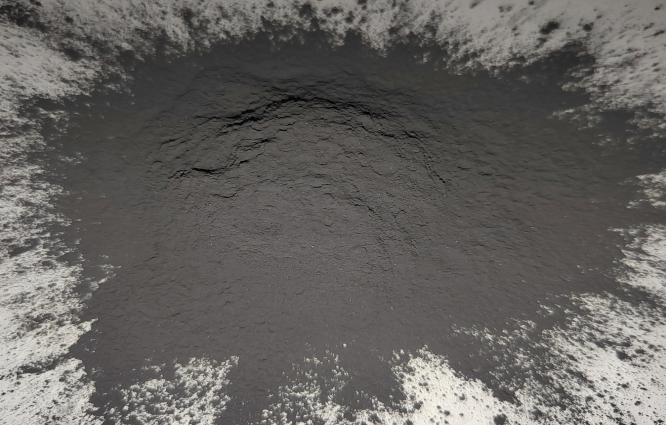

6N High-Purity Silicon Powder is a premium material with 99.9999% purity, featuring a controlled D50 particle size in the micron-sized range (1-10 μm). This ultra-refined powder is critical for advanced materials manufacturing, particularly in high-tech industries. In ceramic materials, it serves as a sintering additive, enhancing density and thermal stability for high-performance ceramics. For lithium-ion battery applications, it acts as a key anode material, improving energy density and cycle life. Additionally, its semiconductor-grade quality supports electronics and powder metallurgy. With versatility across ceramics, energy storage, and beyond, 6N high-purity silicon powder drives innovation in precision-driven sectors.

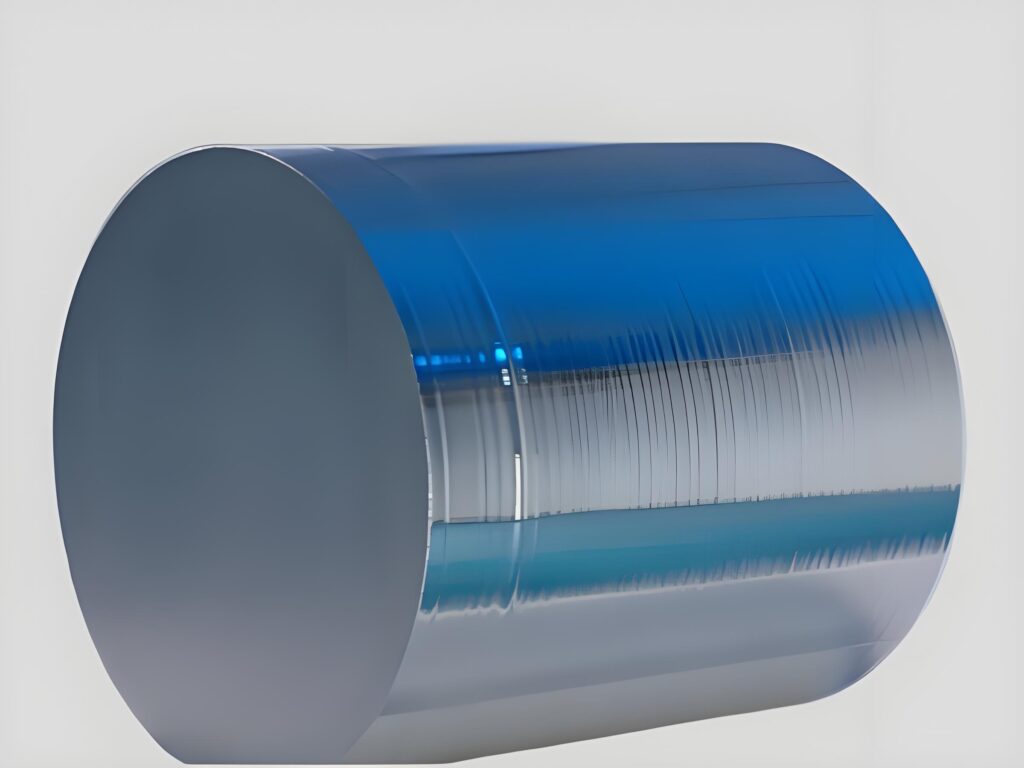

Mono granular silicon and poly silicon particles are essential materials in advanced industrial applications, offering tailored properties for precision processes. With high-purity silicon granules (up to 99.9999%), these particles are widely used in semiconductor manufacturing and photovoltaic technologies, where uniformity and particle size distribution control (1-10mm) are critical. A key application is in silicon particle evaporation coating, where they serve as core materials for thin-film deposition in electronics and optical devices. Additionally, their thermal stability makes them ideal for thermal barrier coatings in aerospace and energy sectors.

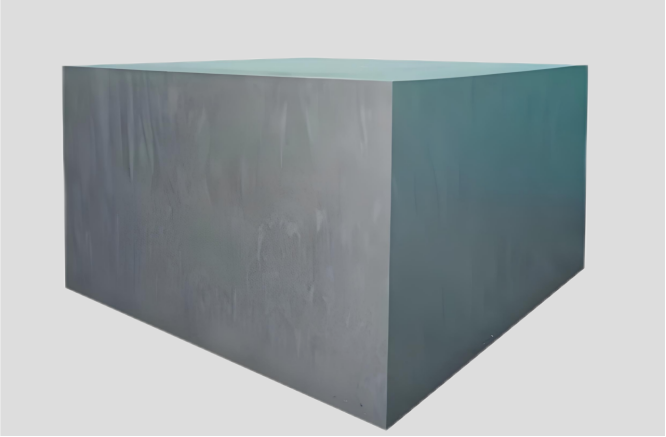

Cast mono crystalline silicon (cast monocrystalline silicon) is a cutting-edge material renowned for its low defect density and large-size manufacturing capabilities, achieving dimensions up to 800x800mm. Designed specifically for semiconductor etching applications, this high-purity silicon delivers exceptional performance in precision silicon components, rivaling traditional monocrystalline silicon in structural integrity and thermal stability. Its ultra-low defect structure ensures minimal impurities, critical for high-yield semiconductor processes, while the large-format design reduces material waste and enhances production efficiency. With properties comparable to monocrystalline silicon, this cost-effective solution is ideal for advanced semiconductor devices, offering defect-free growth and uniformity at scale.