Provide One-stop Solutions For Si Materials

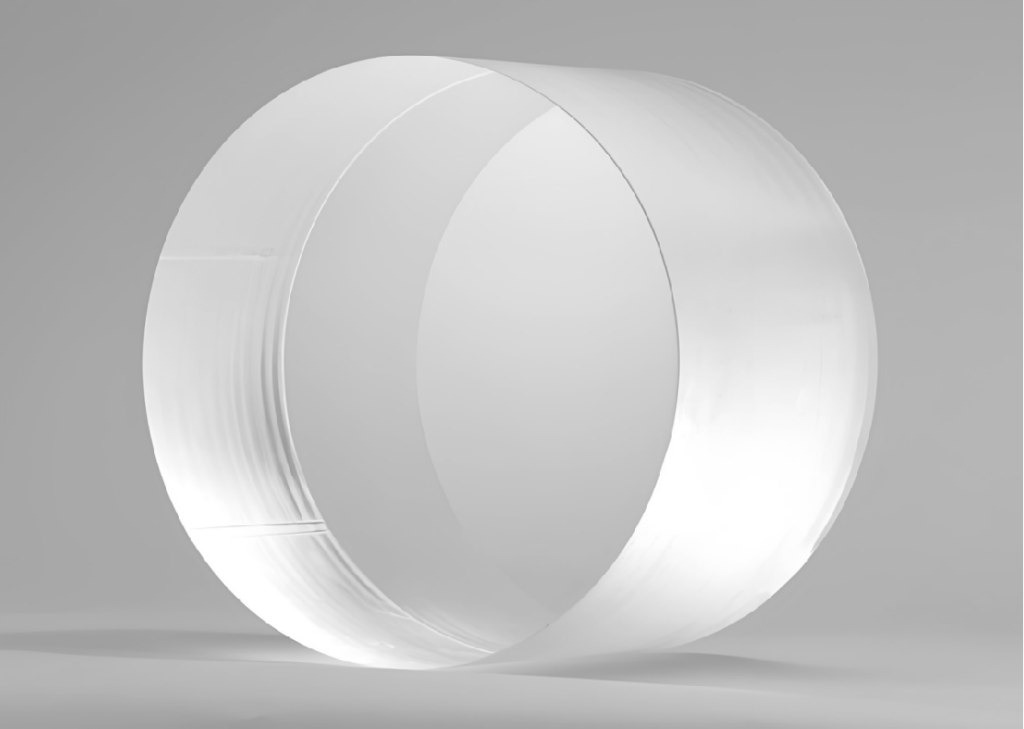

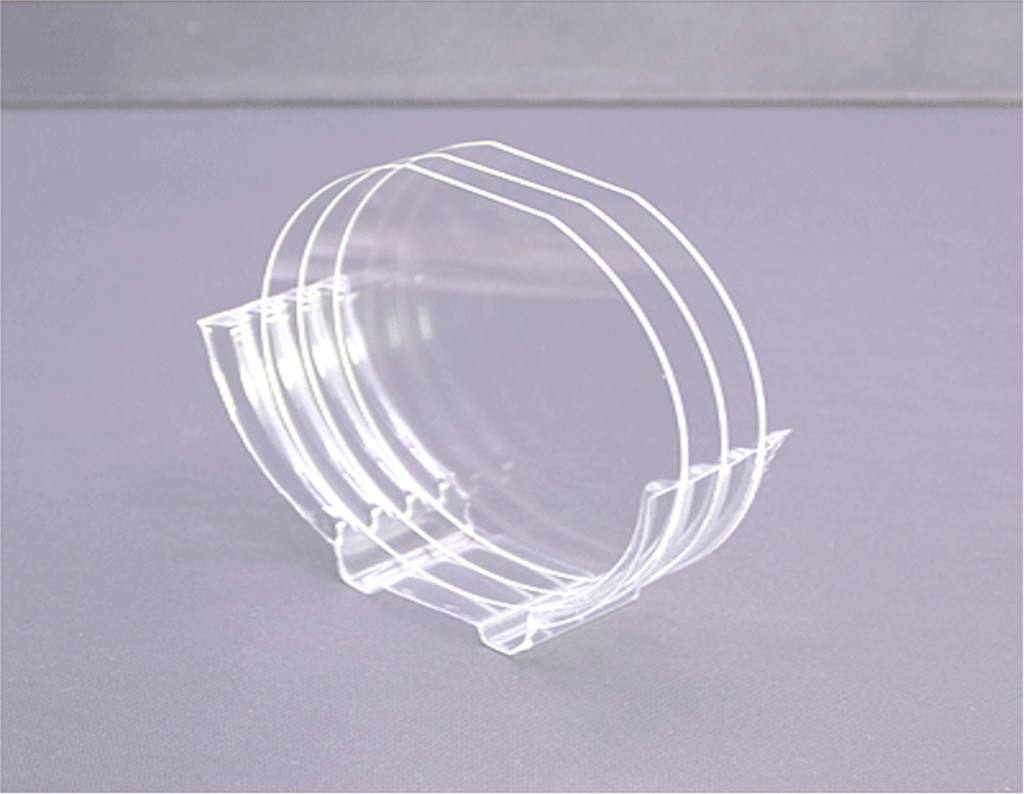

Quartz rings are precision-engineered components crafted from high-purity fused silica, renowned for their exceptional thermal stability, chemical resistance, and optical transparency. These rings play a critical role in advanced industries such as semiconductor manufacturing, where they serve as focus rings in etching processes to ensure precise plasma confinement and uniformity. In sputtering systems, they act as sputtering target supports, enabling thin-film deposition with minimal contamination. Additionally, quartz rings are widely used as flanges in optical devices, providing hermetic seals and dimensional stability in extreme environments.

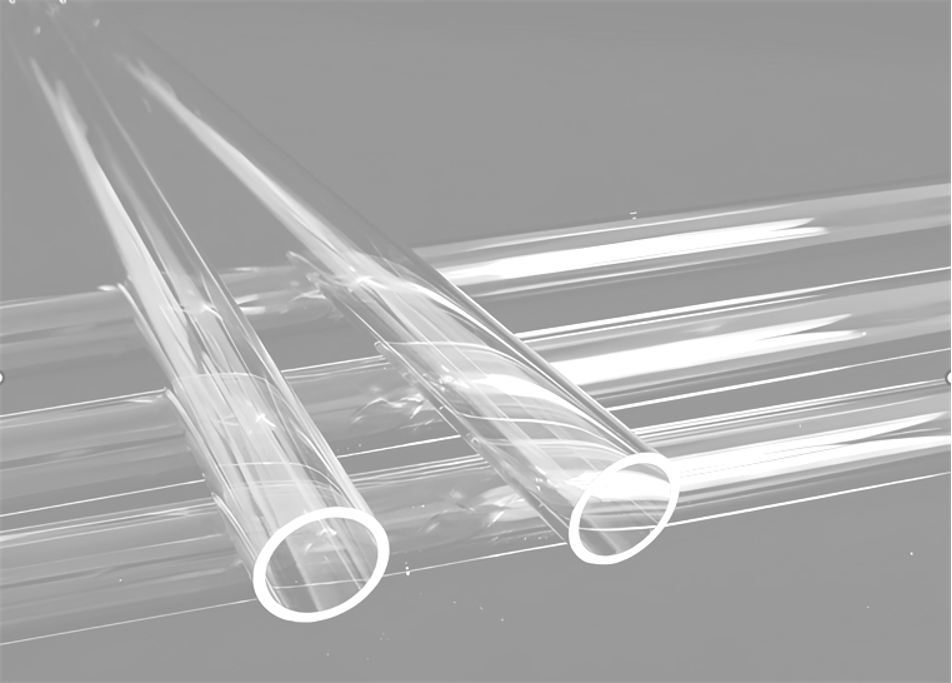

Optical quartz tubes, crafted from high-purity fused silica (99.99% SiO₂), are engineered for precision applications demanding exceptional transparency, thermal stability, and chemical resistance. These tubes exhibit superior UV transmittance (up to 94% in the 200-400 nm range) and withstand extreme temperatures up to 1200°C, making them ideal for semiconductor wafer processing, laser optics, and UV curing systems. Their low thermal expansion coefficient ensures dimensional stability during rapid heating/cooling cycles, while resistance to acids (except hydrofluoric acid) and alkali environments guarantees longevity in corrosive settings. Customizable in diameter (1-800 mm) and length (1-4000 mm), these tubes support advanced industries like solar energy, medical device manufacturing. Partner with trusted suppliers offering ISO-certified products and OEM solutions to meet your specific optical, thermal, and mechanical requirements.

Jingge Semi optical quartz ingots or rods, crafted from 99.99%+ pure fused silica (SiO₂), are engineered to deliver unparalleled performance in high-precision applications. These ingots exhibit ultra-low thermal expansion (5.5×10⁻⁷/K), ensuring dimensional stability during rapid temperature fluctuations up to 1200°C. Their superior UV transmittance (≥90% in the 200–400 nm range) and low hydroxyl content (0.5–1000 ppm) make them ideal for semiconductor photomask substrates, laser optics, and UV curing systems.

Jingge offer UV-grade quartz rods with OH content below 1 ppm, minimizing absorption in critical UV ranges. For specialized needs, custom quartz rod manufacturers provide solutions including surface polishing and precision cutting.

Quartz Wafers are ultra-pure, high-stability substrates widely used in advanced industries such as semiconductor manufacturing, photolithography, and optical device production. Made from high-purity quartz (SiO₂), these wafers exhibit exceptional thermal stability, chemical resistance, and low thermal expansion, making them ideal for applications like photolithography masks, MEMS sensors, and laser optics. Precision-polished to achieve nanometer-level flatness, quartz wafers ensure reliability in extreme environments, including high-temperature semiconductor processes. Their role in enabling cutting-edge technologies, from 5G communications to quantum computing, underscores their critical importance in modern electronics and photonics industries.

Opaque quartz, also known as milky quartz or non-transparent quartz, is a high-purity silicon dioxide (SiO₂) material valued for its exceptional thermal stability, chemical resistance, and durability. Unlike transparent quartz, its opaque appearance arises from microscopic gas bubbles and fluid inclusions formed during the arc-melting process. This unique structure makes it ideal for applications requiring extreme temperature resistance (up to 1450°C) and inertness, such as semiconductor manufacturing, solar cell production, and chemical processing.

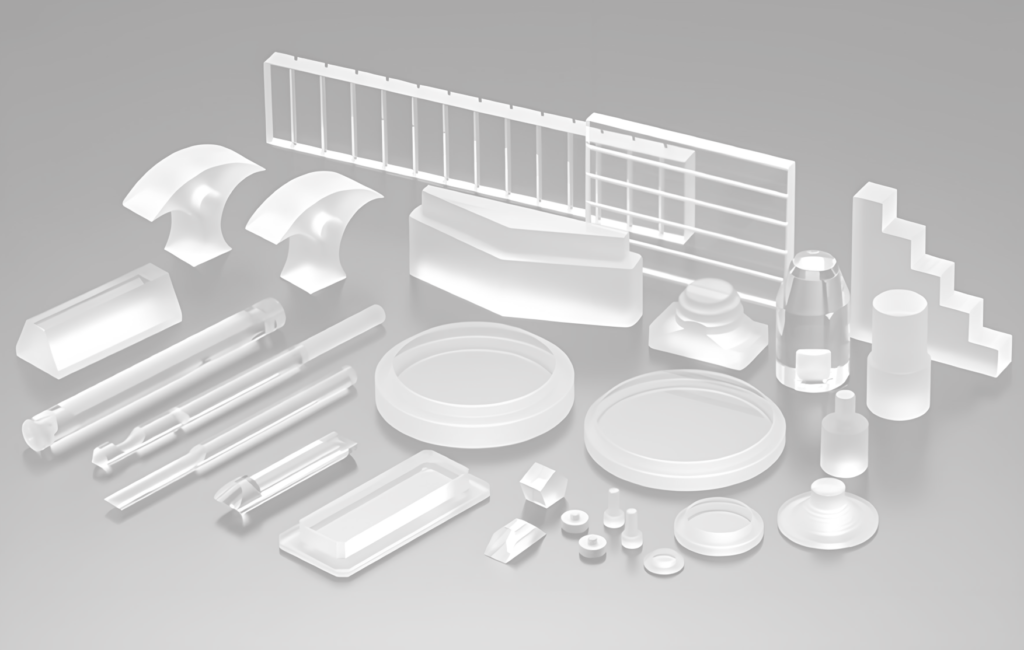

Quartz products, crafted from high-purity silicon dioxide (SiO₂), are indispensable in advanced industries due to their exceptional properties. Our precision-engineered quartz wafers, quartz boats, quartz covers, and other components offer unmatched high-temperature resistance (up to 1,730°C), chemical inertness (except to hydrofluoric acid), and optical transparency across UV to infrared spectra. Ideal for semiconductor manufacturing, they support processes like diffusion, ion implantation, and photolithography, ensuring wafer integrity in harsh environments. In photovoltaics, our quartz crucibles enable efficient silicon crystal growth, while in optics, UV-transparent quartz glass enhances laser and lighting systems. With a focus on customization and semiconductor-grade purity (99.99% SiO₂), our products meet stringent demands in electronics, aerospace, and laboratory equipment. Explore our range of durable, corrosion-resistant quartz solutions designed to elevate performance in critical applications.