Provide One-stop Solutions For Si Materials

Silicon Exhaust Ring is a critical component in semiconductor dry etch equipment, serving as the primary pathway for introducing and distributing etch gases into the reaction chamber. Designed with high-purity silicon for exceptional corrosion resistance and thermal stability, it ensures uniform gas flow and precise control during the wafer etching process. By maintaining vacuum integrity and regulating gas dynamics, the silicon exhaust ring directly impacts etch uniformity and process efficiency, making it indispensable in advanced semiconductor manufacturing for achieving high-precision patterns on wafers.

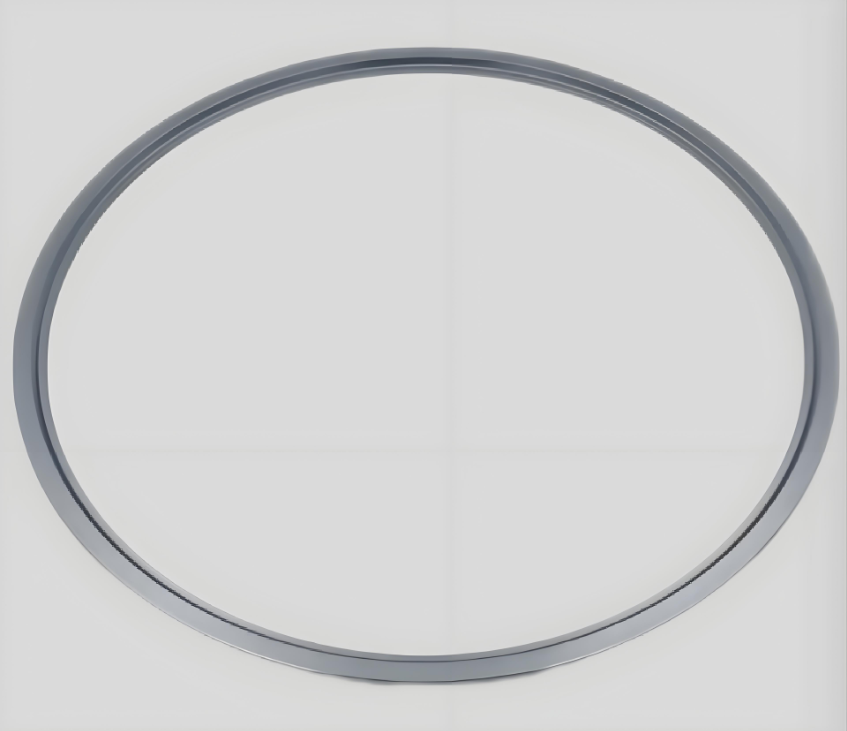

Silicon Ring is a vital component in semiconductor dry etch equipment, designed to regulate gas flow, maintain vacuum integrity, and ensure uniform plasma distribution during wafer processing. Crafted from high-purity silicon, it offers exceptional resistance to corrosive etch gases (e.g., CF₄, Cl₂) and extreme thermal conditions (up to 600°C). Its precision-engineered structure minimizes particle contamination and optimizes etch rate consistency, directly contributing to higher wafer yields and tighter critical dimension control in advanced semiconductor manufacturing nodes (5nm and below).

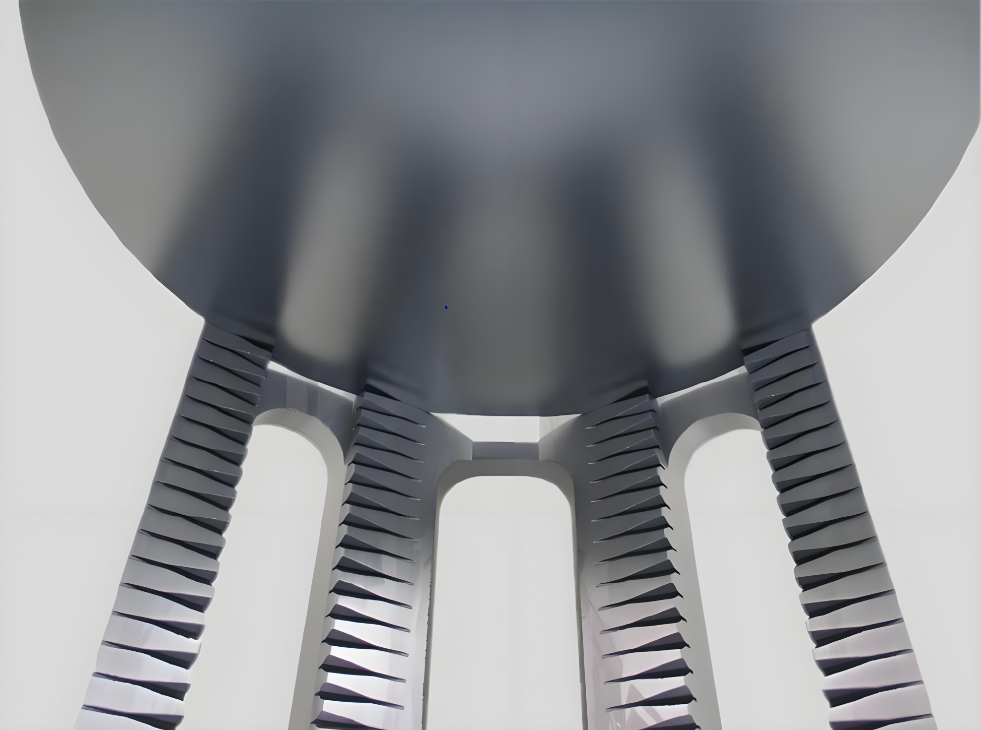

Silicon Showerhead Electrode is a critical component in semiconductor dry etch equipment, functioning as both a gas distributor and RF-powered plasma generator. Crafted from ultra-high-purity silicon, it ensures precise and uniform delivery of reactive gases (e.g., CF₄, Cl₂) into the chamber while maintaining stable plasma density across the wafer surface. Designed to withstand extreme plasma bombardment and temperatures exceeding 500°C, this corrosion-resistant electrode minimizes particle contamination and extends service intervals. Its optimized hole pattern geometry enables sub-5% etch rate variation, directly contributing to high-yield production of advanced logic and memory devices at 3nm nodes and beyond.

Silicon Focus Ring is a precision-engineered component in semiconductor plasma etching equipment, designed to optimize plasma distribution and ensure uniform etching at the wafer edge. Made from ultra-high-purity silicon, it resists corrosion from reactive gases (e.g., CF₄, O₂) and withstands extreme temperatures (up to 700°C) during high-density plasma processes. By minimizing edge exclusion zones and reducing etch rate variability to less than ±1.5%, the focus ring enhances wafer yield and critical dimension (CD) control, particularly in advanced sub-5nm logic and 3D NAND memory manufacturing. Its compatibility with multi-frequency RF systems and automated wafer handling ensures seamless integration into next-generation etch tools.

Monocrystalline Silicon Wafer Boat is a critical component for high-temperature semiconductor processes such as annealing, oxidation, and diffusion. Engineered from ultra-high-purity CZ (Czochralski) monocrystalline silicon, it perfectly matches the thermal expansion coefficient of silicon wafers (150mm, 200mm, 300mm), eliminating friction-induced defects like backside scratches, slip lines, and frontside contamination during thermal cycling. Unlike traditional quartz or silicon carbide boats, this material compatibility prevents particle transfer between wafers and significantly reduces yield loss in advanced nodes. Jingge Semi’s silicon boats undergo precision machining and final cleaning in Class 100 cleanrooms, ensuring contamination-free deployment (particularly heavy metal-free). Pre-conditioning protocols are provided to optimize performance in customer-specific processes, with field-proven results showing >30% reduction in wafer defects and improved chip yield across logic and memory device manufacturing.