Provide One-stop Solutions For Si Materials

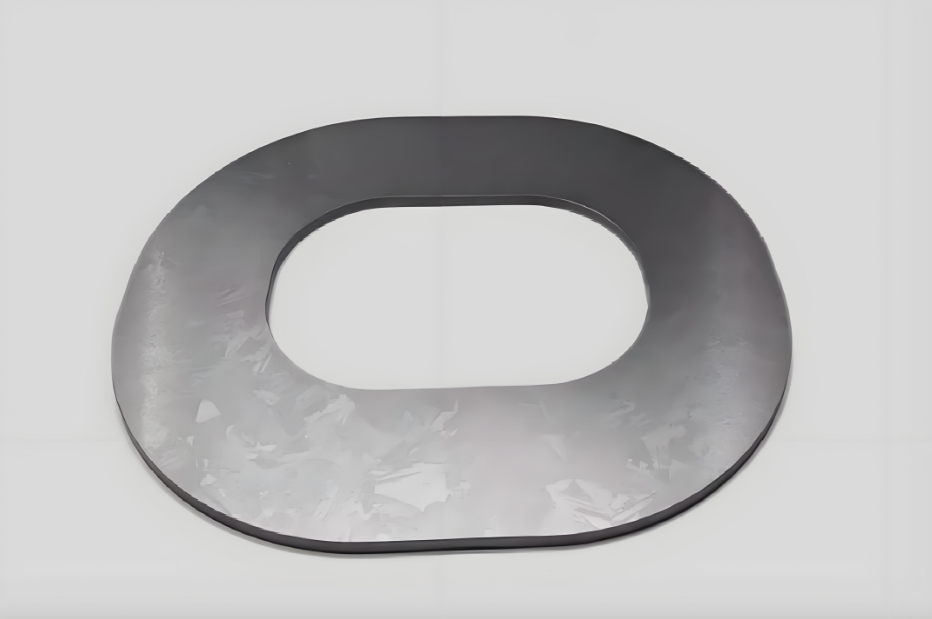

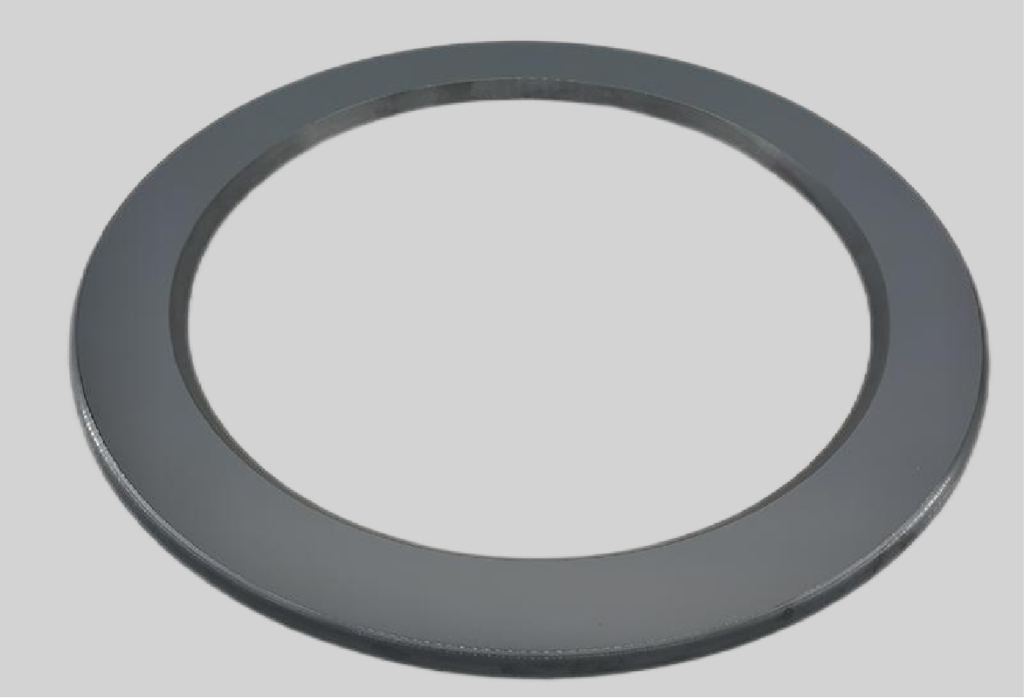

Silicon Annular Sputtering Targets are specialized components for advanced thin film deposition in semiconductor, photovoltaic, and display industries. Monocrystalline Silicon Annular Targets deliver exceptional structural integrity and high-purity performance, while Polycrystalline Silicon Ring Targets offer cost-effective solutions for large-area coating. These targets are available in precisely engineered circular or elliptical geometries, with diameters up to 600mm, enabling uniform material distribution in high-throughput sputtering systems. Customizable resistivity and geometry ensure compatibility with diverse PVD configurations, supporting applications ranging from nanoelectronics to optical coatings.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >6N |

| 2 | Material | / | Mono / Poly |

| 3 | Diameter scale | mm | 0~600 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | <100>/<111>/<110> |

| 7 | Dopant | / | B、P、Ga、As、Sb |

| 8 | Ra | um | ≤0.8 |

Technical Advantages

Precision Geometry for Enhanced Uniformity:Achieve <2% thickness variation in thin films with circular or elliptical silicon ring targets, optimized for rotating magnetron sputtering systems.

Large-Scale Deposition Capability (Up to 600mm Diameter):Enable high-throughput coating for industrial applications using 600mm-diameter annular silicon targets, ideal for solar panels and display manufacturing.

Monocrystalline Purity (99.9999%):Minimize defects in semiconductor-grade films with ultra-high-purity single-crystal silicon ring targets, certified for Class 10 cleanroom processes.

Polycrystalline Cost Efficiency & Flexibility:Reduce material waste by 25% through segmented polycrystalline annular targets, adaptable to complex chamber layouts.

Dual-Resistivity Customization:Tailor electrical properties with low-resistance (<0.01Ω·cm) or high-resistance (>10Ω·cm) silicon rings, supporting MEMS, RF devices, and power electronics.

Edge-to-Center Coating Consistency:Eliminate edge erosion effects with annular target geometry, extending operational lifespan by 30% compared to planar counterparts.

Rapid Prototyping & Scalability:From R&D-scale 100mm rings to 600mm production-grade targets, accelerate time-to-market for optical coatings and advanced ICs.