Provide One-stop Solutions For Si Materials

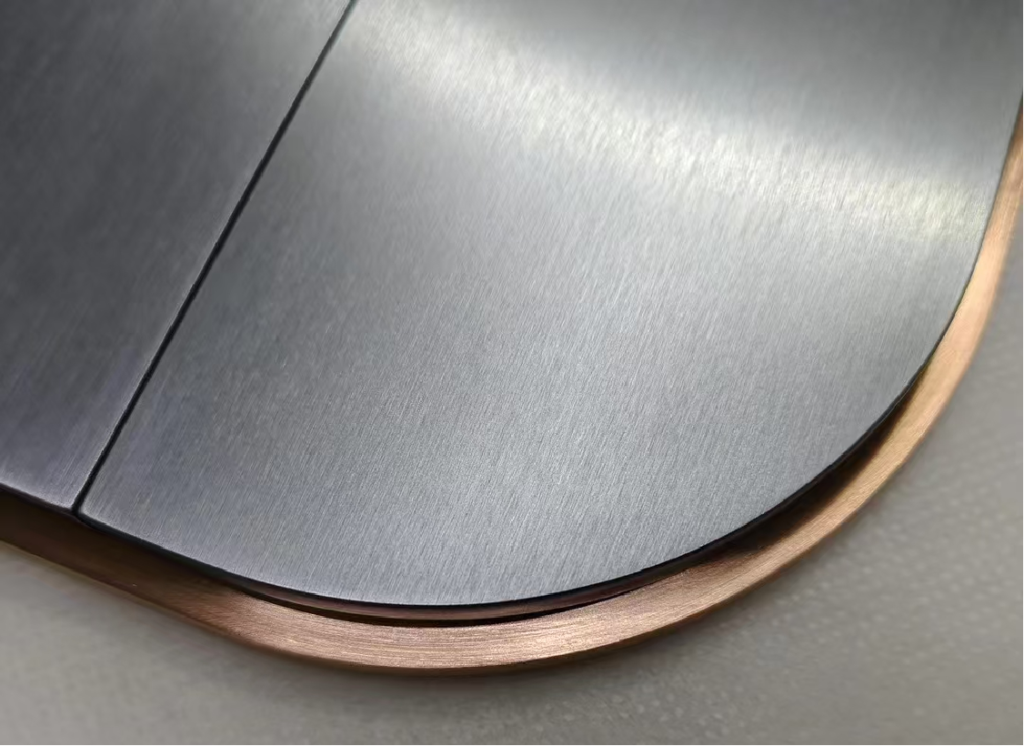

Silicon Square Targets are specialized sputtering materials widely used in semiconductor fabrication, solar cell production, and advanced display technologies. Monocrystalline Silicon Targets provide exceptional structural consistency and high-purity performance, ideal for ultra-precise thin-film applications. Polycrystalline Silicon Targets offer versatile solutions with customizable resistivity levels, including low-resistance (<0.02Ω·cm), medium-resistance (1-5Ω·cm), and high-resistance (>10Ω·cm) options, tailored to meet specific circuit design requirements. With optimized geometry for efficient coating uniformity, these square/rectangular targets enable seamless integration into industrial PVD systems, ensuring high yield and process repeatability across microelectronics and optoelectronic manufacturing.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | >6N |

| 2 | Material | / | Mono / Poly |

| 3 | Diameter scale | mm | 0~2000 / Customizable |

| 4 | Type/Contains | / | P type/ N type |

| 5 | Resistivity | Ω•cm3 | <0.02 / 1~4 / 60~90 |

| 6 | Crystal Orientation | / | 、、 |

| 7 | Dopant | / | B、P、Ga、As、Sb |

| 8 | Ra | um | ≤0.8 |

Technical Advantages

Precision Resistivity Customization:Achieve optimal thin-film conductivity with low-resistance (<0.01Ω·cm), medium-resistance (0.01-10Ω·cm), and high-resistance (>10Ω·cm) silicon targets, tailored for ICs, sensors, and power devices.

Monocrystalline Uniformity & Stability:Maximize coating consistency using single-crystal silicon square targets with <0.5% thickness variation, critical for high-end MEMS and optoelectronic coatings.

Polycrystalline Flexibility & Cost Efficiency:Adapt to diverse PVD systems through multi-segment polycrystalline silicon targets, reducing material waste by 15% versus standard designs.

Edge-to-Edge Deposition Optimization:Enhance thin-film uniformity in rectangular chambers with geometrically optimized square targets, achieving 98% coating homogeneity across large substrates.

High-Purity Material (99.9999%):Minimize defect risks in semiconductor-grade films with ultra-clean silicon targets, certified for ISO 4 cleanroom compatibility.

Scalable Solutions for R&D to Mass Production:From lab-scale prototypes to 300mm+ industrial plates, our targets support seamless integration across CVD, PVD, and ion beam processes.