Provide One-stop Solutions For Si Materials

Home / Products / Si Material / Silicon Powder

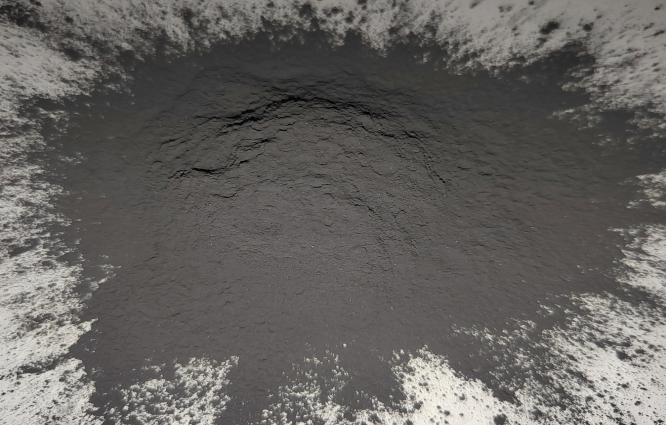

High-purity silicon powder (99.9999%+ purity) with micron-sized particles (1-10μm) is a versatile material essential for advanced industrial processes. In ceramic manufacturing, it serves as a key precursor for producing high-performance silicon nitride powder and tungsten powder, enhancing structural integrity and thermal resistance in final products. The ultrafine silicon particles ensure uniform chemical reactivity and precise sintering behavior, critical for achieving dense, defect-free ceramics. Additionally, semiconductor-grade silicon powder meets stringent requirements for impurity control, enabling its use in microelectronics fabrication. With micron-scale uniformity and ultra-low trace metals, this material is indispensable in advanced materials manufacturing, supporting innovation in electronics, industrial ceramics, and specialized metallurgical applications.

Technical Parameters

| No. | Characteristic | Unit | Spec |

|---|---|---|---|

| 1 | Purity | % | 3N、4N、5N、6N |

| 2 | Particle Diameter | um | 1~5 / 5~10 /10~20 / Customize |

| 3 | Total Metal Impurity | ppm | <1 |

| 4 | C | ppm | ≤100 |

| 5 | H | ppm | ≤25 |

| 6 | O | ppm | <1500 |

| 7 | N | ppm | ≤30 |

| 8 | S | ppm | ≤10 |

Technical Advantages

Poly silicon ingots can be used forprocessing large-sized silicon components and silicon target materials.The purity of silicon ingots produced by Jingge Semi can reach 6N,which is a key basic material for manufacturing semiconductor devices.

Poly silicon ingots can be processed in to large-sized silicon rings for etching purposes,as well as silicon wafers and tubes for sputtering coating purposes.

Jingge Semi full melt and semi-melt processes enable unmatched columnar grain uniformity, minimizing defects and maximizing structural integrity for high-stress applications.

Advanced refining techniques ensure ultra-low oxygen and impurity levels (<1ppb), critical for semiconductor silicon rings requiring extreme electrical stability.

Switch seamlessly between full melt (ultra-dense ingots) and semi-melt (cost-optimized batches) modes to meet diverse industry demands.

- On demands from client,Jingge Semi can make ingot in different shapes and sizes(up to 1200mm diameter).